| CORAL Name: | Oxford-100 |

| Model Number: | |

| Location: | ICL |

| What it does: | Vacuum Deposition/Plasma Etch Tool |

| Introduction: | The Oxford-100 System is an 8" Red tool that also accepts 6" and 4" wafer, and pieces on a handler wafer. This tool allows some III/ V materials and metals. The Deposition chamber has 7 gases available for processing: Ammonia (NH3), Silane (SiH4), Methane (CH4), Nitrous Oxide (N2O), Tetraethylorthosilicate (TEOS), Argon and Nitrogen. The substrate can be heated to 400°C. This chamber can deposit Amorphous Silicon, Silicon Dioxide, Silicon Nitride, Silicon Carbide and TEOS. There are 2 RF power supplies, high and low frequency. The RIE Chamber has 6 gases available for processing: Boron Trichloride (BCl3), Chlorine (Cl2), Sulfur Hexafluoride (SF6), Oxygen, Argon and Nitrogen. There is a heat exchanger on the lower electrode with a range of 5 to 80°C. This chamber can etch Silicon, Silicon Dioxide, Silicon Nitride, Silicon Carbide, Aluminum and some III/V materials. There is a single 300W RF power supply. |

| Safety: | There is an EMO button to the left of the monitor to be used in case of emergency. Pushing this button disables the power to the entire system. Use this button in emergency situations! This button should also if a wafer is going to be broken! In either case, notify the Staff immediately so the system can be checked. Due to the toxic nature of the processing gases, only qualified technical staff is allowed to perform the tasks of turning gases on and off and changing of gas cylinders. Keep your hands away from all moving parts. Do not try to defeat any of the system interlocks. If, while operating this machine, you encounter an issue: report it immediately Using Coral. Report it as either a problem or a shutdown depending on its severity. The staff in charge will address it in a timely fashion. |

| Procedure: | Check reservations in CORAL to insure that you reserved the correct machine in the correct facility for the correct date. Another user may have reservations; it is your responsibility to honor them, if this is the case. Since this is a two-chambered tool, it is possible that one chamber is available for processing while the other is not. This condition will be entered into CORAL as a “Problem” (yellow light) and not a “Shutdown”. A “Shutdown” (red light) means that neither chamber is available for processing. It is imperative that you check CORAL carefully if there is a “Problem”. Open ICL/PECVD-RIE/Oxford-100/Maintenance. Then click on the message and then “show message” in order to determine if the chamber you need is available. Engage the machine in CORAL. The CORAL switchbox light must be "ON" in order to enable the Monitor. There is a local heat exchanger for the RIE module next to the Loadlock. The temperature range is +10C to +80C. It takes about 30 minutes to reach 80C. Please remember to return the temperature to 20C when you are finished processing. Detailed instructions about changing the temperature are on the SOP at the heat exchanger.

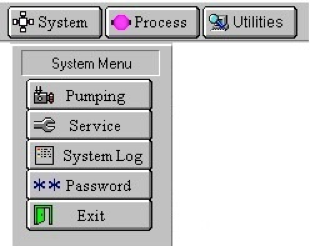

Log on to the system by clicking on the System button at the top of the screen and select Password from the drop down menu. The username is USER and the password is user. To load a wafer into the system, click on the Pumping button from the System menu to display the Pump Control screen.

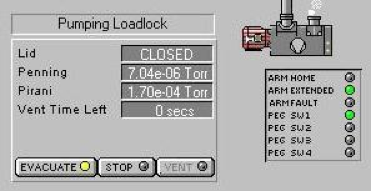

Under the Pumping Loadlock section, click on the STOP Button, and then press VENT. The Vent Time Left feedback will start counting down. When the loadlock reaches atmosphere, open the loadlock lid and place your wafer on the load arm. Close the lid and pump the chamber down by pressing STOP and then EVACUATE. The system will ask for a wafer name:

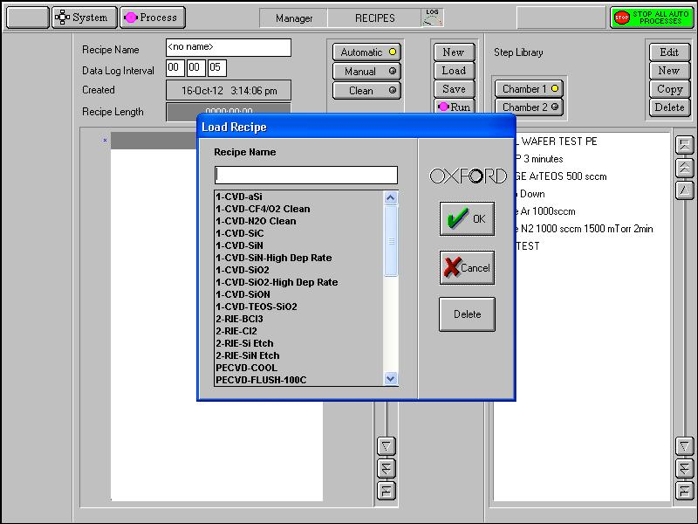

Click on the Load button to pull up the list of available recipes.

The recipe steps will be displayed on the screen.

Click on the deposition step and choose EDIT to adjust the recipe time. Enter the required time in the Step Time boxes, and then click Ok to save the change.

The editor will close and return to the main recipe page. Click on the Run button to begin processing the wafer. The wafer progress may be monitored from the appropriate chamber screen, and the time to completion is detailed in the Process Control section.

When the wafer has completed running, it will be returned to the loadlock for removal. STOP then VENT Remove the wafer and either load the next one or pump down the loadlock. Close the lid and pump the chamber down by pressing STOP and then EVACUATE. Disengage from CORAL |

| Author: | Bob Bicchieri and Donal Jamieson, 4/14 |