Self-powered Long-range Wireless Microsensors for Industrial Applications

- Category: Circuits & Systems

- Tags: anantha chandrakasan, nathan ickes

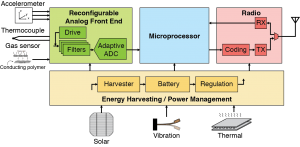

Figure 1: Block diagram of the planned sensor node. Optimized, energy-efficient sensor front end and radio components will allow the entire node to be powered from ambient energy harvested from solar, vibration, or thermal sources.

Improved monitoring of industrial equipment through the use of vast networks of small, easily installed, long-lasting, reliable wireless sensor nodes has the potential to increase worker safety, decrease down time, and even minimize unnecessary preventative maintenance. While critical systems are already likely to be highly instrumented and monitored, a large, modern industrial installation (such as an oil refinery, for example) may contain thousands of pumps, fans, motors, and other ancillary equipment that is monitored only through periodic, manual inspections. We are developing wireless microsensors to improve and automate the monitoring of this balance-of-plant equipment.

Figure 1 shows a block diagram of the planned sensor nodes. A reconfigurable analog front end will interface to the sensors themselves. Mechanical failures often develop slowly and can be detected early from abnormal vibrations and temperatures or minor gas leaks. Therefore, while the front end will be adaptable to a variety of sensor types, we will primarily focus on accelerometers and thermocouples, as well as a new conductive polymer sensor for organic vapors, which is also being developed for this project.

Designing an efficient radio and network protocol is another key effort of this project. The target applications will require long- range (at least 100m) communication between the sensor nodes and the base station and high densities (up to 10,000 nodes per base station). We are investigating ways to improve existing protocols by reducing synchronization requirements and incorporating new coding techniques (such as spinal codes), to shift more of the power consumption to the base station, where energy is less constrained.

Once deployed, the sensors must function for up to twenty years without maintenance, so each node will be entirely powered by energy scavenged from its environment. Solar power is an attractive source for sensors deployed outdoors, but we are also investigating vibration and thermal harvesting, as these energy sources are readily available in many industrial applications and would allow sensors to be deployed in much less accessible locations.