Mechanisms for Intrinsic Stress Evolution during Deposition of Polycrystalline Films

- Category: MEMS & BioMEMS

- Tags: carl thompson, hang yu

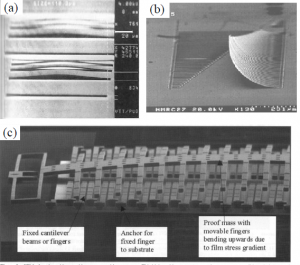

Complex kinetic processes are involved during the growth of polycrystalline films, which is typically carried out far from equilibrium. Minor changes in processing conditions can lead to tremendous differences in surface morphology, grain structure, and residual stress in the films. This result strongly influences their performance and reliability in nano- and micro-electromechanical devices and systems (N/MEMS)[1]. Control of the residual stress is especially important in the devices based on micro-beam structures, such as electrically actuated switches and accelerometers. For example, for doubly-supported beams, an average compressive stress as small as 10 MPa can cause buckling, while a tensile stress can cause changes in the beam’s stiffness. Figure 1 shows examples of problems caused by residual stresses in released micro-structures and devices.

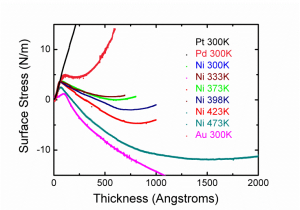

Through in situ real-time measurements we have studied the intrinsic stress evolution of a number of materials at different homologous temperatures (deposition temperature divided by the melting temperature) for several materials (Figure 2). One general trend can be found: the stress becomes more compressive when the homologous temperature is higher. In particular, at intermediate homologous temperatures, the instantaneous stress changes from compressive to tensile during film thickening. Previous models[2][3][4] are inadequate to explain this transition behavior. By characterizing the film microstructure as a function of the film thickness, we conclude that this transition originates from the increase of grain size during film thickening, which has two consequences. First, it changes the bulk stress of the film during deposition and causes a tensile component of the instantaneous stress. Second, it changes the grain size dependence of the compressive component, the magnitude of which is controlled by the competition between adatom-2D island incorporation and adatom-GB incorporation.

- Problems caused by residual stress in MEMS[5].

- Surface stress (stress-thickness product) as a function of film thickness during deposition of polycrystalline films curves of Pt, Pd, and Au.

- C. T. Leondes, MEMS/NEMS : handbook techniques and applications ,Springer, New York, 2006). [↩]

- F. Spaepen, “Interfaces and stresses in thin films,” Acta Materialia , vol. 48, pp. 31-42, Jan. 2000. [↩]

- C. Friesen, and C. V. Thompson, “Reversible stress relaxation during pre-coalescence interruptions of volmer-weber thin film growth,” Physical Review Letters, vol. 89 p.126103, Sept. 2002. [↩]

- E. Chason et al., “Origin of compressive residual stress in polycrystalline thin films,” Physical Review Letters, vol. 88, vol. 15, p. 156103, Apr. 2002. [↩]

- C. T. Leondes, MEMS/NEMS : handbook techniques and applications ,Springer, New York, 2006). [↩]