Stretchable Pressure- and Shear-sensing Skin Printed from PDMS

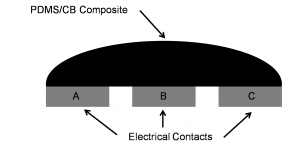

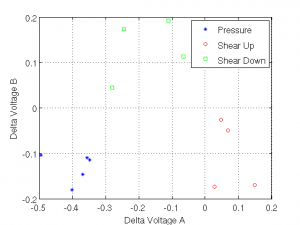

In the fields of robotics and prosthesis design, there is need for inexpensive, wide-area pressure- and shear-sensing arrays that can be integrated into a flexible and stretchable skin analog[1],[2]. This project seeks to meet this need by building combined pressure and shear sensors based on the well documented piezoresistive property of composites made from PDMS and carbon black (CB)[3],[4]. These sensors can be printed by extruding the uncured composite and can be molded directly into a solid PDMS membrane to form a sensing skin that is water- and heat-resistant, flexible, and stretchable. The sensor concept consists of three electrical contacts, arranged linearly, with the PDMS/CB composite deposited on top of them. When this arrangement is exposed to pressure, the resistance between the center contact and each of the edge contacts changes equally. However, when sheared, the resistance changes differently between the center contact and the two edge contacts. In this way the effects of pressure and shear can be separated; see Figure 1. In fabrication, a silver/PDMS composite is used to form the contacts, a PDMS/CB composite is used to form the sensors, and pure PDMS is used to form the bulk of the skin. Each of these materials is extruded onto a plastic membrane, which is removed after heat-curing. Due to the early point in development and fabrication, the sensors have excessive drift that makes quantitative measurements difficult. However, subtracting the resting voltages (representing the resistances of each half of the sensor) measured before shear or pressure is applied from those measured after their application and plotting these differences enables observation of the separation of pressure and shear; see Figure 2. At present this method works for a carefully selected area of the sensor and degrees of pressure and shear.

- Figure 1: Cut-away side-view diagram of a sensor at rest. Note that the PDMS skin into which this sensor is embedded is not shown. Under pressure the strain in each half of the sensor will be roughly equal, causing roughly equal resistance change between contacts A and B and between contacts B and C. However, under left-to-right shear, the left half of the sensor will be in tension while the right half will be in compression, causing unequal stain and therefore an unequal resistance change.

- Figure 2: Plot of the change in voltage drop across one half of the sensor versus the change in voltage drop across the other half of sensor for application of pressure and two directions of shear. The appearance of points for each type of deformation in different quadrants of the plot demonstrates that the sensor can separate pressure and shear. Note that this preliminary data was generated under specific conditions on a single sensor.

- M.-A. Lacasse et al., “Characterization of the Electrical Resistance of Carbon-Black-Filled Silicone: Application to a Flexible and Stretchable Robot Skin,” Robotics and Automation (ICRA), 2010 IEEE International conference on, pp. 4842-4848, 3-7 May 2010. [↩]

- T. Yamada et al., “A stretchable CNT strain sensor for human-motion detection,” Nature Nanotechnologyvol. 6, pp. 296-301, Mar. 2011. [↩]

- R. Struempler and J. Glatz-Reichenbach, “Conducting polymer composites,” J Electroceramics, vol. 3 no. 4, pp. 329-346, Oct. 1999. [↩]

- F. M. Yaul and J. H. Lang, “A Flexible Underwater Pressure Sensor Array Using a Conductive Elastomer Strain Gauge,” Journal of Microelectromechanical Systems,vol. 21, no. 4, Aug. 2012. [↩]