Nanoporous Elements with Layer-by-layer Assembly in MEMS with a Focus on Microfluidic Bioparticle Separation

- Category: MEMS & BioMEMS, Nanotechnology

- Tags: allison yost, brian wardle

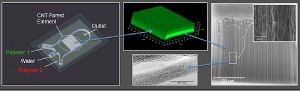

We have integrated ultra-porous (99% porous) elements (nanoporous forests of vertically aligned carbon nanotubes (VACNTs)) in MEMS, showing their use in microfluidic applications for bioparticle isolation and health diagnostics. Distinct from works where the effects of fluids on VACNT elements resulted in either structural deformation or catastrophic forest collapse[1], our approach enables creation of high aspect ratio (~1-mm) nanoporous elements and preserves their shape under flow-through conditions. Figure 1 shows a device consisting of a patterned and (wet) functionalized VACNT forest integrated into a PDMS microfluidic channel.

Compared to state-of-the-art designs that exploit solid materials (e.g., silicon, PDMS) for the structural features, our nanoporous elements enable flow around and through the VACNT elements, enhancing physical interaction between the particles in the flow and the functional elements. The large surface-to-volume ratio of nanoporous materials yields a significant increase in the functional surface area (~250-500X for the layouts analyzed in our works[2] ), with permeability comparable to that of macro-scale porous materials[3], thus further promoting bioparticle capture[4]. To utilize these attributes, assembly of polymer films on individual carbon nanotubes via layer-by-layer (LbL) techniques was explored. Conformal coating surrounding the VACNTs provides the opportunity to control intra-CNT spacing as well as surface functionality.

Initial work on VACNT-LbL assemblies has been performed on various geometries at the same flow conditions. FITC-PAH-SPS at appropriate pH levels was used to perform LbL. Preliminary results indicate conformal coating on both the inside and outside surfaces of the VACNT wall elements. Effects of flow conditions, other polymer systems, and surface functionalization are topics of ongoing work. Optimization of functionalizing similar polymer films on flat surfaces has been performed, with the goal of applying the same surface chemistry to CNT microfluidic elements for bioparticle capture and manipulation.

Figure 1: Left: microfluidic device containing a forest of carbon nanotubes through which fluids pass. Center top: a confocal microscope image of the nanotube forest after the nanotube trees have been individually coated uniformly with molecular layers of polymers containing green fluorescent dye. Right: Scanning and transmission electron microscope (SEM and TEM) images of the nanotube forest edge. Center Bottom: TEM image showing an individual nanotube coated conformally with the polymer layers.

- D. N. Futaba, K. Hata, T. Yamada, T. Hiraoka, Y. Hayamizu, Y. Kakudate, O. Tanaike, H. Hatori, M. Yumura, and S. Iijima. “Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes,” Nature Materials, vol. 5, pp. 987-994, 2006. [↩]

- G. D. Chen, F. Fachin, M. Fernandez-Suarez, B. L. Wardle, and M. Toner, “Nanoporous elements in microfluidics for multiscale manipulation of bioparticles,” Small, vol. 7, pp. 1061-1067, 2011. [↩]

- F. Fachin and G.D. Chen, M. Toner, and B. L Wardle, “Integration of bulk nanoporous elements in microfluidic devices with application to biomedical diagnostics,” Journal of Microelectromechanical Systems, vol. 20, no. 6, pp. 1428-1438, 2011. [↩]

- G. D. Chen, F. Fachin, E. Colombini, M. Toner, and B. L. Wardle, “Nanoporous micro-element arrays for particle interception in microfluidic cell separation, “ Lab on a Chip, vol. 12, pp. 3159-3167, 2012. [↩]