Lubricant-Impregnated Nanotextured Surfaces for Efficient Heat Transfer during Condensation

- Category: Energy, Materials, Nanotechnology

- Tags: kripa varanasi, sushant anand

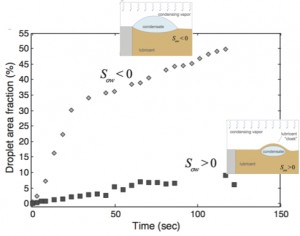

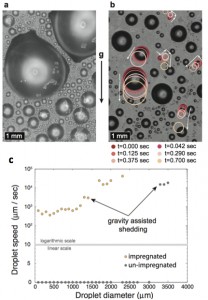

Despite years of advancement in making energy systems more efficient, the predominant mode of condensation seen in large-scale industrial processes is still filmwise condensation. Replacing the filmwise condensation mode with dropwise condensation promises large improvements in heat transfer efficiency that will reduce the cost in material, water consumption, and size of the systems. In this regard, the use of superhydrophobic surfaces fabricated by texturing surfaces with nano/microstructures has been shown to lead decreases in contact line pinning of millimetric drops, resulting in fast shedding. However, these useful properties are lost during condensation as droplets that nucleate within the texture grow larger by virtue of condensation while still adhering to the surface. This Wenzel pinning can, however, be eliminated by introduction of a lubricant[1][2][3][4]. Recently we have shown that liquid-impregnated surfaces can overcome many limitations of conventional superhydrophobic surfaces during condensation[5]. Here we show aspects related to condensation on liquid surfaces and how relations among the surface tension of the encapsulating liquid and the condensing liquid determine the condensation and subsequent shedding behavior for condensing droplets (Figure 1). The characteristics of condensed droplet behavior on these surfaces are compared with that on conventional un-impregnated superhydrophobic surfaces (Figure 2) to show how the use of lubricant impregnated surfaces may lead to large enhancement in heat transfer and energy efficiencies ((Anand, S.; Paxson, A. T.; Dhiman, R.; Smith, J. D.; Varanasi, K. K., Enhanced Condensation on Lubricant-Impregnated Nanotextured Surfaces. ACS Nano 2012, 6, (11), pp. 10122-10129.)).

- Figure 1: Plot comparing variation of surface area fraction covered by condensed water droplets versus time on surfaces impregnated with Krytox (Sow > 0, solid squares) and BMIm (Sow < 0, open diamonds). The ESEM experiments were conducted under identical conditions (pressure 800 Pa, substrate temperature ~3.6 oC, beam voltage 25 kV, and beam current 1.7 nA). In the analysis, t = 0 s is defined as the first frame in which water drops can be identified

- Figure 2: Comparison of condensation on hierarchical superhydrophobic and ionic liquid-impregnated surfaces with identical texture at macroscales. (a) Representative image of condensation on superhydrophobic surface comprising nanograss microposts; large pinned droplets are seen be- fore shedding from the surface. (b) Representative image of condensation on nanograss microposts impregnated with ionic liquid. Both small and large droplets are highly mobile; colored circles are provided as visual guides for depicting droplet motion. (c) Median speed of droplets as a function of drop diameter for unimpregnated (black circles) and impregnated surfaces (orange circles). The data are plotted on a mixed linear/logarithmic scale in order to capture both the zero value and substantial range of magnitudes in droplet speed.

- Quéré, D., Non-sticking drops. Reports on Progress in Physics 2005, 68, (11), pp. 2495-2532. [↩]

- Wong, T. S.; Kang, S. H.; Tang, S. K. Y.; Smythe, E. J.; Hatton, B. D.; Grinthal, A.; Aizenberg, J., Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, (7365), pp. 443-447. [↩]

- Smith, J. D.; Dhiman, R.; Varanasi, K. K. Liquid-encapsulating surfaces: overcoming the limitations of superhydrophobic surfaces for robust non-wetting and anti-icing surfaces, Bulletin of the American Physical Society, 2011. [↩]

- Smith, J. D.; Dhiman, R.; Anand, S.; Reza-Garduno, E.; Cohen, R. E.; McKinley, G. H.; Varanasi, K. K., Droplet mobility on lubricant-impregnated surfaces. Soft Matter 2013, 9, (6), pp. 1772-1780. [↩]

- Anand, S.; Paxson, A. T.; Dhiman, R.; Smith, J. D.; Varanasi, K. K., Enhanced Condensation on Lubricant-Impregnated Nanotextured Surfaces. ACS Nano 2012, 6, (11), pp. 10122-10129. [↩]