High-throughput Electrospinning of Nanofibers from Batch-microfabricated Arrays

- Category: MEMS & BioMEMS

- Tags: luis velasquez-garcia, philip ponce de leon

Nanofibers’ unique morphological properties promise to make them a key engineering material across many disciplines. In particular, the large specific surface area of the porous webs they form make them highly desirable as multifunctional layers in protective soldier clothing; scaffolds in tissue engineering; and components in devices such as fuel cells, solar cells, and ultra-capacitors[1]. However, their integration into almost all of these technologies is unfeasible as a result of the low throughput and high cost of current production methods. The most common process for producing nanofibers involves applying strong electric fields to polar, high molecular weight polymeric liquids pumped through a syringe in what is known as electrospinning. Electrospinning is the only known technique that can generate nanofibers of arbitrary length and has tremendous versatility as it can create non-woven or aligned mats of polymer, ceramic, semiconducting, and/or metallic fibers.

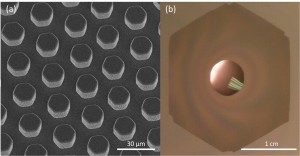

We implement high-throughput arrays of externally fed, batch-microfabricated electrospinning emitters that are precise, simple, and scalable. We fabricate monolithic, linear emitter arrays that consist of pointed structures etched out of silicon using DRIE and assemble these into a slotted base to form a two-dimensional array. By altering the surface chemistry and roughness of the emitters, we can modify their wetting properties to enable “hemi-wicking”[2] of fluid through the micro-texture (Figure 1). The interplay between electric, surface tension, and viscoelastic forces governs the fluid transport and fiber formation. We achieve more than 30 seconds of continuous, stable electrospinning simultaneously from 9 emitters in a two-dimensional array less than 1 cm2 using bias voltages under 15kV (Figure 2). This represents a 4-fold increase in run time compared to similar externally fed approaches[3] and a 7-fold increase in emitter density compared to state-of-the-art MEMS electrospinning sources[4]. Future work should explore denser arrays and integration of a proximal extractor electrode.

- Figure 1: a) Micropillar surface roughness and (b) hemi-wicking spread of a droplet through the roughness.

- Figure 2: 3×3 array of 5-mm tall emitters producing PEO nanofibers in the stable regime.

- V. Thavasi, G. Singh, and S. Ramakrishna, “Electrospun nanofibers in energy and environmental applications,” Energy Environ. Sci., vol. 1, pp. 205-221, 2008. [↩]

- D. Quéré, “Wetting and Roughness,” Annu. Rev. Mater. Res., vol. 38, pp. 71-99, 2008. [↩]

- C. Chang, K. Limkrailassiri, and L. Lin, “Continuous near-field electrospinning for large area deposition of orderly nanofiber patterns,” Appl. Phys. Lett., vol. 93, 123111, 2008. [↩]

- Y. Srivastava, M. Marquez and T. Thorsen, “Multi-jet electrospinning of conducting nanofibers from microfluidic manifolds,” J. Appl. Polym. Sci., vol. 106, pp. 3171-3178, 2007. [↩]