Batch-Microfabricated RPA for Ion Energy Measurements

- Category: MEMS & BioMEMS

- Tags: eric heubel, luis velasquez-garcia

Plasma diagnostic tools are required in numerous fields, from experimental physics to aerospace and beyond. Various sensors exist to capture plasma saturation current and plasma potential, and will infer other properties through theory. The retarding potential analyzer (RPA) is device that will directly measure ion energy, a property of interest monitoring exterior craft conditions at hypersonic speeds. Through microfabrication, our device expands the present state-of-the-art to achieve improved mechanically enforced grid alignment, while maintaining the required micron-scale features.

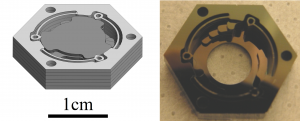

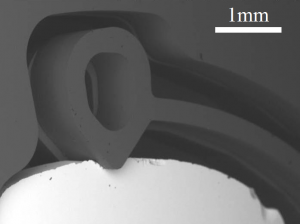

Advantages of enforcing alignment across successive RPA electrodes was already demonstrated in a hybrid device yielding a threefold increase in signal amplitude[1]. In utilizing microelectromechanical system (MEMS) batch-fabrication techniques, alignment precision is refined to the order of 1μm[2]. This MEMS RPA exemplifies the same modularity as the hybrid device, such that grids may be interchanged within the same housing, and otherwise incompatible fabrication techniques might be used. Figure 1 shows the schematic of a complete sensor and the corresponding six-wafer housing stack. Alignment in the assembled device is enforced by curved silicon springs in the housing (Figure 2) which allow for a slight mismatch in nominal and actual grid and housing dimensions, and can accommodate changing dimensions due to thermal expansion. Another advantage of microfabrication is the batch-processing of devices in an effort to drive down costs. MEMS RPA housings are manufactured 30 devices at a time.

Measurements with our MEMS RPA have shown an additional jump in peak signal strength resulting in an order of magnitude increase over its conventional counterpart[3]. In using thicker silicon electrodes over mesh grids, the device is expected to be more robust when exposed to harsher environments. Finally, if batch-fabrication can lead to a more widely available ion energy sensor, this device could find application in monitoring micromachining processes in-situ.

- Figure 1: MEMS RPA schematic consisting of housing and grids (left), completed RPA housing (right)[4]

- Figure 2: MEMS RPA housing spring clamping a grid into alignment[4]

- E. V. Heubel, A. I. Akinwande, and L. F. Velásquez-García, “MEMS-Enabled Retarding Potential Analyzers for Hypersonic In-Flight Plasma Diagnostics,” Technical Digest of the 2012 Hilton Head Workshop on Physical Sensors, Hilton Head, SC, pp. 324 – 327, 2012. [↩]

- B. Gassend, L. F. Velásquez-García, and A. I. Akinwande, “Precision in-plane hand assembly of bulk-microfabricated components for high-voltage MEMS arrays applications,” Journal of Microelectromechanical Systems, vol. 18, no. 2, pp. 332-346, Apr., 2009. [↩]

- E. V. Heubel and L. F. Velásquez-García, “Batch-Fabricated MEMS Retarding Potential Analyzer for High-Accuracy Ion Energy Measurements,” Technical Digest of the 26th IEEE International Conference on Micro Electro Mechanical Systems, Taipei, Taiwan, pp. 661 – 664, 2012. [↩]

- E. V. Heubel and L. F. Velásquez-García, “Batch-Fabricated MEMS Retarding Potential Analyzer for High-Accuracy Ion Energy Measurements,” Technical Digest of the 26th IEEE International Conference on Micro Electro Mechanical Systems, Taipei, Taiwan, pp. 661 – 664, 2012. [↩] [↩]