Silicon Nanowires for Energy Storage in Microsystems

Micro-batteries provide a critical component for self-powered autonomous microsystems. Lithium-ion batteries provide relatively high energy storage capacities. Significant improvement in energy storage capacities over current generation lithium-ion batteries is achievable by using silicon as the anode material. Silicon has the highest known Li capacity, up to 4.4 lithium atoms per silicon atom. However, lithiation of silicon results in large volume changes that cannot be sustained in monolithic forms such as fully dense films or substrates. To employ silicon-based lithium batteries, nanostructured silicon nanowires with high surface-to-volume ratios and superior mechanical properties over bulk are being investigated [1] [2] .

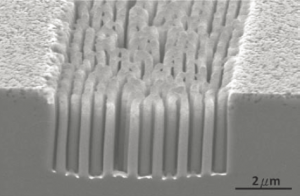

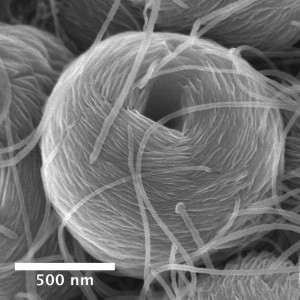

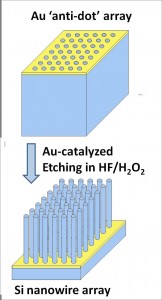

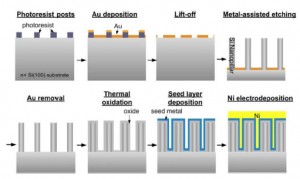

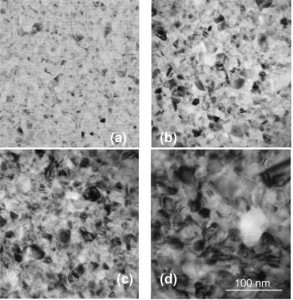

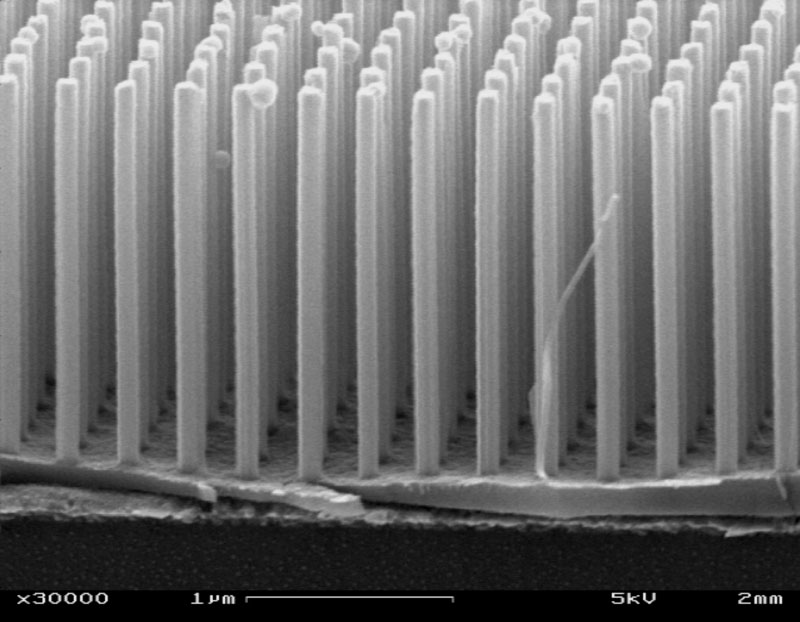

We use metal-catalyzed etching (MCE) to fabricate the silicon nanowires, a process that offers low-cost, room temperature processing of silicon. The process takes advantages of a thin, patterned metal film that catalyzes the etching of silicon when immersed in an HF solution with an oxidant such as H2O2. MCE can be used to create of large (>1 cm2) arrays of perfectly ordered Si-NWs with periods down to 40 nm, diameters down to 20 nm, and aspect ratios up to 200 to 1 [3] . These high-volume filling arrays are being used for studies of lithiation. Amorphous silicon-based nanowire arrays on various substrates are being explored for enhanced cyclability (Figure 1).

Figure 1: Amorphous silicon nanowires on glass using MCE [1] . These wires are expected to better accommodate the stresses associated with lithiation.

- C. K. Chan, H. Peng, G. Liu, K. McIlwrath, X. F. Zhang, R. A. Huggins, and Y. Cui, “High-performance lithium battery anodes using silicon nanowires,” Nature Nanotechnology, vol. 3, pp. 31-35, 2008. [↩] [↩]

- C. K. Chan, R. Ruffo, S. S. Hong, R. A. Huggins, and Y. Cui, “Structural and electrochemical study of the reaction of lithium with silicon nanowires,” J. of Power Sources, vol. 14, pp. 34-39, 2010. [↩]

- S. W. Chang, V. P. Chuang, S. T. Boles, C. A. Ross, and C. V. Thompson, “Densely-packed arrays of ultrahigh-aspect-ratio silicon nanowire fabricated using block copolymer lithography and metal-assisted etching,” Adv. Funct. Mater. vol. 19, pp. 2495-2500, 2009. [↩]