- Authors: F. M. Yaul, A. P. Chandrakasan

Wireless sensor nodes (WSNs) have a great potential to save energy and improve safety when applied to building energy monitoring, structural monitoring, and environmental monitoring. These systems typically comprise a low-power microprocessor, a wireless transceiver, analog signal conditioning circuits, and an analog-to-digital converter (ADC). However, in order to be sustained by harvested ambient energy, these systems must operate within a tight power budget. Today, circuit blocks like amplifiers and ADCs have individually been highly optimized, but achieving greater power savings requires approaching the system as a whole.

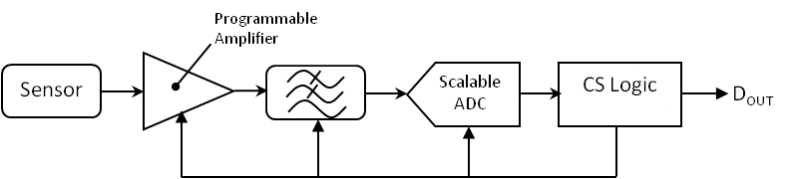

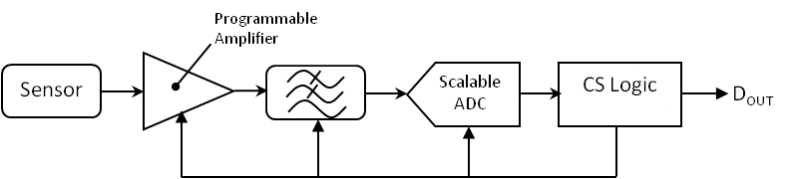

This work focuses on power reduction of the sensor interface circuitry through resolution and sampling frequency scaling [] and compressed sensing algorithms [] . Combining the control provided by the algorithms with the scalability designed into the interface circuits creates a fully self-contained adaptive sensor interface that scales its sampling frequency and resolution, among other parameters, based on the local information content of the incoming signal.

Figure 1: Block diagram of adaptive sensor interface.

- Authors: M. E. Woo, F. M. Yaul, V. Bulovic, J. H. Lang, M. S. Triantafyllou

- Sponsorship: NOAA-MIT Sea Grant College Program, Singapore-MIT Alliance for Research and Technology

A pressure sensor array is under development for unmanned undersea vehicles (UUV). This project is inspired by the lateral line sensory organ in fish, which enables some species to form three-dimensional maps of their surroundings [] [] . The canal subsystem of the organ can be described as an array of pressure-sensors [] . The lateral line allows fish to perform a variety of actions, from tracking prey [] to recognizing nearby objects [] [] . Similarly, by measuring pressure variations on the surface of an UUV, an engineered pressure-sensor array supports the identification and location of obstacles for navigation.

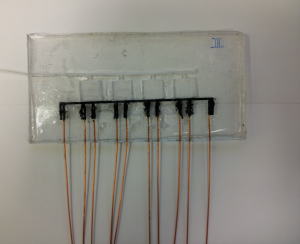

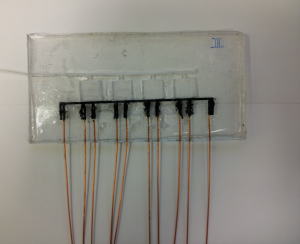

To be compatible with the doubly-curved surface of a typical UUV hull, the pressure sensor array must be flexible. Further, it is desirable that the array be amenable to wide-area fabrication. Correspondingly, the design pursued here is fabricated primarily from a PDMS polymer, some parts of which are doped with conducting nanoparticles so as to become piezoresistive. As shown in Figure 1 below, a pressure sensor array consists of piezoresistive strain-gauges patterned onto PDMS membranes suspended over cavities formed in a PDMS substrate [] . The resistance of each strain gauge is measured using a four-point probe array with a common current source shared by all sensors. The strain-gauge resistance can be related to the deflection of its corresponding membrane, and hence the pressure difference across the membrane. All cavities are connected together so that all pressure sensors have a common reference.

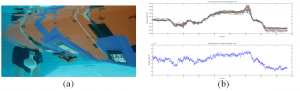

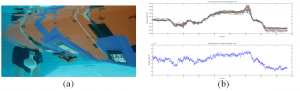

During the past year, flexible pressure sensor arrays were mounted on the side of a kayak for open-water tests, as shown in Figure 2a below. The pressure measurement from one sensor is shown in Figure 2b together with measurements from nearby commercial reference sensors. The similarity of the measurements demonstrates the functionality of the PDMS pressure sensors in an uncontrolled environment.

-

-

Figure 1: A linear PDMS pressure sensor array with four sensors; the membranes are approximately 1 cm square.

-

-

Figure 2: (a) A linear pressure sensor array attached to the bottom of a kayak; (b) the response to kayak maneuvers of one pressure sensor in the PDMS pressure sensor array (bottom trace) and the response of several nearby commercial pressure sensors to the same maneuvers (top traces).