CMP Slurry Abrasive Particle Agglomeration Modeling

- Category: Nanotechnology

- Tags: duane boning, joy johnson

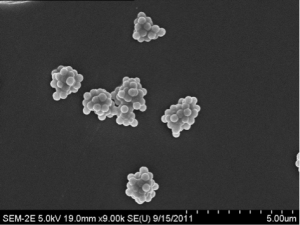

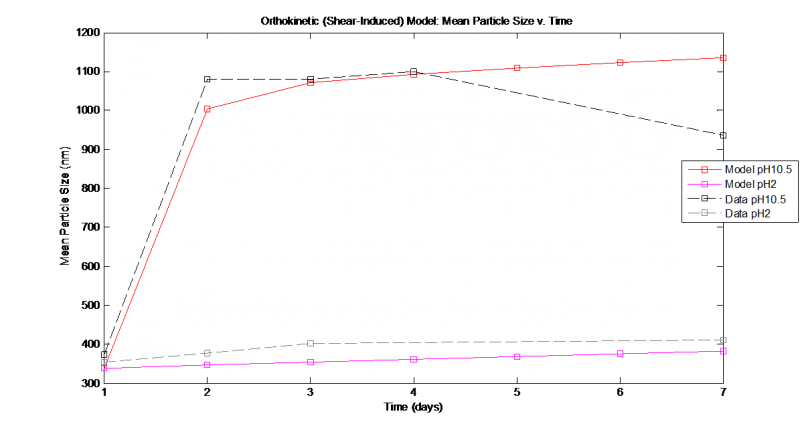

Previously we proposed a particle agglomeration model for chemical mechanical planarization (CMP) with the primary motivation of understanding the creation and behavior of the agglomerated slurry abrasive particles during the CMP process. The particles are known to be a major cause of defectivity, poor consumable utility, and process variation. In this year’s work, we extend the model to include the effect of shear forces during CMP and to utilize a more sophisticated model of the double layer interactions between slurry abrasive particles in order to account for the charge effects of chemical additives. We also conducted fundamental experiments to observe agglomeration in non-commercial, experimentally created simple slurry mixtures (see Figure 1).

Our model considers the CMP slurry composition as a colloidal suspension of charged colloidal particles in an electrically neutral aqueous electrolyte. First, a theoretical relationship between the measurable chemical parameters of the slurry’s electrolyte (pH, conductivity/ionic strength), the surface potential of the abrasive particles, and subsequent zeta potential is established. Secondly, this potential is employed in a modified DVLO interaction potential model to determine the pair-wise particle interaction potentials due to both the attractive van Der Waals forces and repulsive electrostatic interactions as a function of the chemical parameters. Then, the total interaction potential created is used to define a stability ratio, which is combined with the shear rate of the process to calculate the orthokinetic aggregation rate constant. Finally, these rate constants are used in a discrete population balance framework to describe the growth of the slurry abrasive particle size distribution with respect to time and composition in a matter analogous to physical particle size distribution measurements.

We focus on the fundamental chemical and mechanical mechanisms by which slurry abrasive particles intended for planarization form agglomerates. We predict the formation of these agglomerates using measureable parameters and metrics of the slurry. The theoretical model described is empirically validated using literature and our own fundamental experimental data (shown in Figure 2).

Our model provides both a qualitative and quantitative description of agglomeration of slurry abrasive particles during CMP that will enable more accurate process control, increased consumable utility, and possible reduction of defectivity. Current work is focused on experimental development, validation, and extension of the theoretical model.

- Figure 1: SEM of experimentally-created slurry at basic pH.

- Figure 2: Model vs. experimental data for experimental slurry.