Templated Solid-State Dewetting for Pattern Formation

- Category: Materials, Nanotechnology

- Tags: Carl Thompson

Vapor deposited thin films are rarely stable, so that when they are heated to temperatures at which atomic diffusivities are sufficiently high, they will dewet to form isolated islands. This liquid-like process, driven by surface energy minimization, can occur well below the film’s melting temperature, so that structure evolution occurs via surface self-diffusion on the solid film. Film dewetting (sometimes called agglomeration) has long been a problem in the processing of micro-systems. Dewetting of silicides, metal films, and even silicon-on-insulator films has been a concern that required careful process control to avoid. At the same time, dewetting has also come to be appreciated as a means of producing catalysts for nanowire and nanotube growth and, increasingly, arrays of more complex structures.

In the past, we have studied dewetting of polycrystalline to understand the conditions required to avoid dewetting, as well as to develop techniques for control of dewetting to give ordered arrays of catalysts. In recent work, we have studied dewetting of single crystal films, using epitaxial Ni films on MgO as a model system. We found that pre-patterning of the films can be used to reproducibly guide the formation of complex structures. Pattern formation is strongly affected by the size of the patterning relative to the film thickness, and by crystalline anisotropy of the surface energy. Shape evolution is governed by a specific set of fundamental processes that include formation and pinch-off of rims to form wires [1] , corner and edge instabilities [2] , edge faceting [3] , and Rayleigh-like instabilities to form islands from lines [4] . Relatively simple pre-patterning can be used to reproducibly form patterns with more complex shapes and smaller feature sizes.

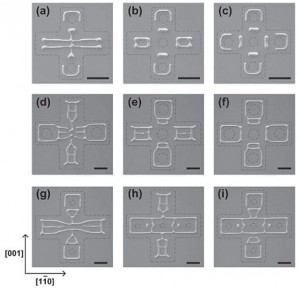

- Figure 1: Dewetting of square patches patterned from a Ni(110) film. For the first row, the initial pattern edges (indicate by the dashed lines) lay along [100] (vertical) and [1-10] (horizontal) in-plane directions. In the second and third row, the edges lay along [111] directions. Scale bars indicate 10 µm. (Note that the initial patch size was smaller for the third row than for the second row.)

- Figure 2: Dewetting of cross patches with pre-patterned internal circular holes patterned from a Ni(110) film. Dashed lines indicate the initial pattern. Scale bars indicate 10 µm.

- J. Ye and C. V. Thompson, “Regular pattern formation through the retraction and pinch-off of edges during solid-state dewetting of patterned single crystal films,” Physics Review, vol. B82, p. 193408, 2010. [↩]

- J. Ye and C. V. Thompson, “Mechanisms of complex morphological evolution during solid-state dewetting of single-crystal nickel thin films,” Appl. Phys. Letts., vol. 97, p. 071904, 2010. [↩]

- J. Ye and C. V. Thompson, “Anisotropic edge retraction and hole growth during solid-state dewetting of single crystal nickel thin films,” Acta Materialia, vol. 59, p. 582, 2011. [↩]

- J. Ye and C. V. Thompson, “Templated solid-state dewetting to controllably produce complex patterns,” Advanced Materials, vol. 23, p. 1567, 2011. [↩]