Controlling the Intrinsic Stresses in Polycrystalline Metallic Films for N/MEMS Applications

- Category: MEMS & BioMEMS

- Tags: Carl Thompson

Polycrystalline metallic thin films are vital in a wide variety of applications, including microelectronics, plasmonics, magnetic storage, N/MEMS and catalysis. Because mechanical properties strongly influence their reliability and performance, understanding and controlling the intrinsic stresses in as-deposited films are of great importance. When the capacitance or multi-beam laser technique is used, real-time stress measurements can be performed during thin film deposition. The measurement results do not only provide a useful tool to define the stress evolution history but also an insightful picture for the study of structure evolution processes. When combining the in situ stress measurement with other characterization techniques and theoretical modeling, we are able to move towards a comprehensive understanding of the underlying atomic processes during Volmer-Weber growth.

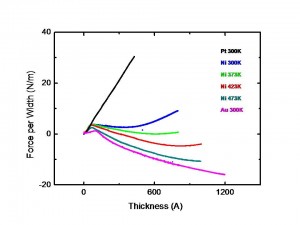

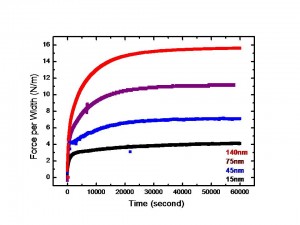

We have experimentally studied the intrinsic stress evolution at different homologous temperatures. Figure 1 shows the general trend—compressive stress is favored at higher temperatures and tensile stress is favored at lower temperatures. This trend indicates that the compressive stress generation processes are thermally activated. Furthermore, we found the incremental stress changes from compressive to tensile during growth at intermediate homologous temperatures, e.g., Ni at 398K. The origin of the compressive-tensile transition is not known exactly. None of the previous models [1] [2] [3] are able to explain the transition behavior. We have also studied the stress behaviors during long interruptions of gold films. Particularly, we studied the long interruptions of gold films with different thicknesses. Figure 2 demonstrates that the total released stress is dependent on the film thickness during long interruptions. This result strongly suggests that the stress relaxation during long interruptions is a bulk process. Meanwhile, we found abnormal grain growth occurs in as-deposited gold film at room temperature. By calculating the densification stress due to grain growth and comparing its value with the measured bulk relaxation stress, we conclude that grain growth is the main process of bulk stress relaxation.

- Figure 1: Stress-thickness curves of fcc metals at different homologous temperatures.

- Figure 1: Stress-thickness curves of fcc metals at different homologous temperatures.

- F. Spaepen,“Interfaces and stresses in thin films,” Acta. Materialia, vol. 48, pp. 31-42, 2000. [↩]

- C. Friesen and C.V. Thompson, “Reversible stress relaxation during precoalescence interruptions of Volmer-Weber thin film growth, Physical Review Letters, vol. 89, no. 2, p.126103, Sept. 2002. [↩]

- E. Chason, B. W. Sheldon, L. B. Freund, J. A. Floro, and S. J. Heame, “Origin of compressive residual stress in polycrystalline thin films,” Physical Review Letters, vol. 88, no. 15, p. 156103, Apr. 2002. [↩]