Sub-10-nm Fabrication Based on Templated Self-assembly of Block Copolymer

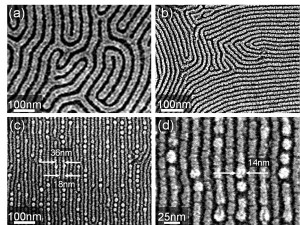

Figure 1: (a) SEM image of untemplated PS-PDMS (MW 45.5 kg/mol). (b) SEM image of untemplated PS-PDMS (MW16k). (c) Self-assembled low molecular weight PS-PDMS lines with templates. (d) Magnified image of Figure 1(c).

Templated block copolymer (BCP) self-assembly is attractive for fabricating few-nanometer-scale structures at high throughput ((I. Bita, J.K. Yang, Y.S. Jung, et al., “Graphoepitaxy of self-assembled block copolymers on two-dimensional periodic patterened templates,” Science, vol. 321, no. 5891, pp. 939-943, Aug. 2009.)). Among several morphologies of block copolymer, cylindrical morphology has a big potential because it can be used for IC circuit fabrication. In our previous work, we fabricated complex structures that can be components of IC circuit by physically defined templates and self-assembled block copolymers [1]. We used polystyrene-polydimethylsiloxane (PS-PDMS) with a molecular weight (MW) of 45.5 kg/mol and a pitch of 36 nm. Because the pitch of cylindrical morphology block copolymer varies in direct proportion to its molecular weight, low- molecular-weight block copolymer is more desirable for making smaller structures.

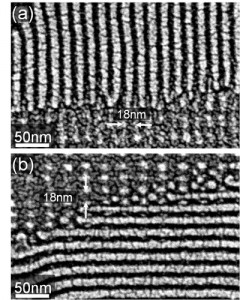

Figure 2: SEM image of self-assembled PS-PDMS (MW 16 kg/mol) lines templated by a smaller post when (a) the horizontal pitch is 18 nm (b) the vertical pitch is 18 nm.

Here, we applied the same strategy to low-molecular-weight block copolymer (MW 16 kg/mol) for making smaller structures. Figure 1a shows a scanning electron micrograph (SEM) of untemplated cylindrical morphology PS-PDMS whose molecular weight is 45.5 kg/mol. Compared with Figure 1a, Figure 1b shows much smaller structures made by lower-molecular-weight (MW 16 kg/mol) PS-PDMS. To template the self-assembly of low-molecular-weight PS-PDMS, the substrate surface was modified physically by hydrogen silsesquioxane (HSQ) and electron-beam lithography. After development, the surface of template was coated by PDMS monomer to attract PDMS blocks in PS-PDMS block copolymers. When the horizontal pitch is double the natural pitch of low- molecular-weight PS-PDMS, self-assembled cylindrical morphology PS-PDMS lines are aligned vertically (Figure 1c).

We also tried smaller templating posts whose diameter and height are less than 10 nm. A smaller post induces less strain to PS-PDMS block copolymer lines, so it is more desirable for templating low-molecular-weight block copolymer. To make such small posts, spin coated HSQ film was partially dissolved by MIBK, and then electron-beam lithography was carried out. SEM images of Figure 2 show vertically and horizontally aligned polymer lines depending on pitches.

References

- J.K. Yang, Y.S. Jung, J. Chang, et al., “Complex self-assembled patterns using sparse commensurate templates with locally varying motifs,” Nature Nanotechnology, vol. 5, pp. 256-260, Mar. 2010. [↩]