Solid-state Dewetting of Single-crystal Films

When thin films are heated to sufficiently high temperatures, they will usually dewet (or agglomerate) to form isolated islands. This process occurs while the film is still solid and is driven by capillary energy minimization, and often occurs via surface self-diffusion at temperatures well below the film’s melting temperature [1] [2]. It can be disastrous if dewetting occurs during the processing of thin films. In particular, it has recently become an issue in the processing of especially thin silicon films on insulating substrates (SOI). On the other hand, regular morphologies of dewetted single crystal SOI thin films [3] [4] show the possibility of producing ordered arrays of crystallographically-aligned catalysts by way of single crystal thin-film dewetting. To understand the conditions required to avoid dewetting and to realize the potential of using detwetting to create ordered functional structures, we are carrying out basic studies of dewetting of single-crystal films using epitaxial Ni grown on MgO as a model system.

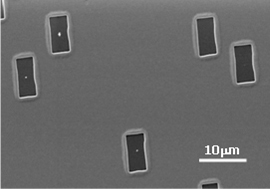

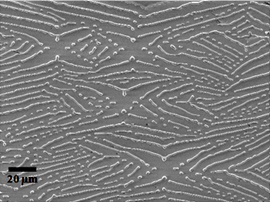

We have studied morphological evolution during the dewetting of 120-nm-thick single-crystal (100) and (110) Ni thin films on MgO substrates. We observed specific dewetted morphologies that depended on the initial crystallographic orientations of the films. Morphological evolution occurs through the nucleation and growth of holes that have simple in-plane faceted shapes (Figure 1). By analyzing the anisotropy of retraction velocities for pre-patterned edges, we found that the anisotropy of the edge-retraction velocity has a profound effect on the specific shapes of the holes. In the late-stage evolution of growing holes, instabilities in the rims that develop around the edges of holes lead to a more rapid growth at corners. This phenomenon is responsible for development of complex geometries such as the one shown in Figures 2. We have characterized and modeled these phenomena and are now studying behavior during dewetting of thinner films.

References

- Jiran E, C. V. Thompson, “Capillary Instabilities in Thin-Films,” Journal of Electronic Materials, vol. 19, p. 1153 (1990). [↩]

- Jiran E, C. V. Thompson, “Capillary Instabilities in Thin, Continuous Films,” Thin Solid Films, vol. 208, p. 23 (1992). [↩]

- R. Nuryadi, Y. Ishikawa, Y. Ono, M. Tabe, “Thermal agglomeration of single-crystalline Si layer on buried SiO2 in ultrahigh vacuum,” Journal of Vacuum Science & Technology B, vol. 20, p. 167 (2002). [↩]

- Z. A. Burbanudin ZA, R. Nuryadi, Y. Ishikawa, M. Tabe. “Transition from wire formation to island formation in thermal agglomeration of a (111) silicon-on-insulator layer,” Thin Solid Films, vol. 508, p. 235 (2006). [↩]