Optical-loss Reduction in High-index-contrast Chalcogenide Glass Waveguides via Thermal Reflow

Chalcogenide glasses (ChG’s) have recently emerged as a promising material candidate for high-index-contrast (HIC) photonic devices, featuring almost unlimited capacity for composition and property tailoring, wide infrared transparency, and high Kerr nonlinearity accompanied with low two-photon absorption (TPA). However, despite the tight optical confinement in HIC waveguides and the ensuing integration benefits, HIC waveguides typically suffer high propagation loss, mainly due to increased optical scattering from sidewall roughness. Here we present rapid thermal reflow as an effective approach for sidewall roughness and optical-loss reduction in HIC chalcogenide waveguide devices [1].

Strip waveguides with a width of 800 nm and a height of 400 nm in thermally evaporated As2S3 film (n = 2.37) are patterned via lift-off in this study. The entire patterning process has been carried out on a 500-nm CMOS line. Thermal reflow of the as-patterned waveguide devices is carried out at different temperatures (± 5 ºC) on a pre-heated hotplate in a nitrogen-filled glove box (oxygen and water vapor impurity < 1 ppm). After heat treatment, the samples are immediately transferred onto an aluminum heat-sink held at room temperature to minimize dwelling time at intermediate temperatures. Before optical characterization, a 3-μm thick layer of SU8 polymer is spin-coated onto the waveguides to prevent oxidation.

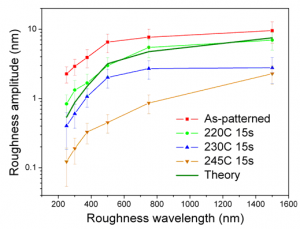

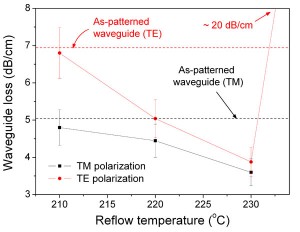

Power spectral density functions of waveguide sidewall roughness are shown in Figure 1. Generally the roughness amplitude diminishes with the roughness wavelength. Further, roughness with smaller spatial wavelength exhibits a more significant amplitude reduction. Such an observation is discussed and consistently explained within the framework of a kinetic theory [1]. Figure 2 plots the transmission loss in As2S3 waveguides after reflow treatment at different temperatures. The optical loss decrease after 15-s reflow from 210°C to 230°C is consistent with the trend of sidewall roughness smoothing, and it thus can be associated with the scattering loss reduction. However, despite the continuing trend of roughness reduction at increased reflow temperature, optical loss in As2S3 waveguides sharply increases to ~ (20 ± 6) dB/cm after 15-s reflow at 245°C. Based on material and device characterization results, we attribute the loss increase to the partial evaporation of As2S3 glass, which leads to waveguide thickness reduction and hence increased bending loss and modal mismatch loss between the straight and bent sections in a racetrack resonator. The evolution of optical loss in As2S3 is also investigated using waveguide modal analysis, and good agreement between simulation and measurement is confirmed.

References