Metallic and Other Glasses for MEMS

Chalcogenide glasses are widely used as “phase change materials” for optical data storage media in rewritable compact discs (CD±RW) and rewritable digital video disks (DVD±RW, DVD-RAM). Recently, they have also shown high potential for use in phase-change random access memories (PC-RAMs or PRAMs), which might replace flash memories in the future. In these applications, information storage is accomplished by reversible amorphization and crystallization. Metallic glasses have also recently generated interest because of their having a combination of high elastic moduli and fracture strengths. They have been used, for example, as torsional springs in micro-mirror arrays. In both types of applications, the mechanical properties of films in the glassy state are important in determining their functionality and reliability. Of particular interest is the stability in the glassy state and stress changes associated with crystallization, both of which can be studied through measurements of cantilever displacements associated with crystallization.

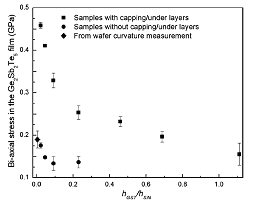

In prior work we have shown that the stress change associated with crystallization of chalcogenides depends strongly on the thickness of films, and on whether or not the films are capped with materials with high stiffness (Figure 1). This large dependence is the result of inelastic accommodation of a component of the large volume change (~6%). The yield stress of the glasses is strongly thickness- and encapsulation-dependent [1] [2].

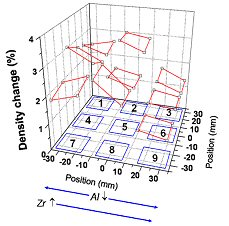

In more recent studies we have focused on metallic glasses, both for applications as memory media and as mechanical components in MEMS devices. We have used combinatorial deposition on cantilever arrays to characterize the volume change on crystallization in the binary Cu-Zr [3] and ternary Cu-Zr-Al systems [4]. We found significant and complex dependences of the volume/stress change on composition (Figure 2). These variations were also found to correlate with the ease with which these alloys of specific compositions could be deposited or quenched into the glassy state. We are now measuring the compositional dependence of the elastic modulus, thermal expansion coefficient, and hardness of as-deposited and annealed metallic glasses.

- Figure 1: Crystallization-induced stress in Ge2Sb2Te5 (GST) layers for different GST-to-SiN cantilever thickness ratios, hGST/hSiN. Tensile stress is defined to be positive. The filled squares are data points for samples with ZnS–SiO2 capping and underlayers [2].

- Figure 2: Density changes associated with crystallization as a function of the position of nine die with cantilever arrays in a sputtering system with three separate Al, Cu, and Zr sources. Compositions vary over ranges of about 10% (see [4]).

References

- J.A. Kalb, Q. Guo, X. Zhang, Y. Li, C. Sow, and C.V. Thompson, “Phase-Change Materials in Optically Triggered Microactuators,” J. of Microelectromechanical Systems 17, 1094 (2008) [↩]

- Q. Guo, M. Li, Y. Li, L. Shi, T.C.C., J.A. Kalb, and C.V. Thompson, “Crystallization-induced stress in thin phase change films of different thicknesses,” Appl. Phys. Lett., 93, 221907 (2008). [↩] [↩]

- Y. Li, Q. Guo, J.A. Kalb, and C.V. Thompson, Matching Glass-Forming Ability with the Density of the Amorphous Phase,” Science 322, 1816 (2008). [↩]

- Q. Guo, J. H. Noh, P. K. Liaw, P. D. Rack, Y. Li, C. V. Thompson, “Density change upon crystallization in amorphous Zr-Cu-Al thin films,” Acta Materialia 58, 3633 (2010). [↩] [↩]