Metalized Carbon Nanotubes for Energy Applications

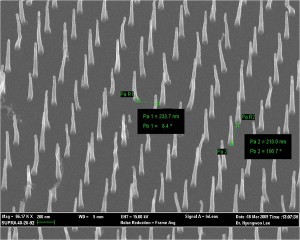

Figure 1: Aligned carbon nanotubes grown from nickel nanodot catalysts via PECVD. Diameter 80nm, length 3µm, spacing 5µm.

Electrodes formed from nanowire arrays have been shown to improve charge transport across a wide range of energy generation and energy storage devices. The electrode surface area and numerous current paths of these arrays ensure both redundancy and high current density [1] [2]. Metalized carbon nanotube (CNT) electrodes have the potential to provide the same high density current path. Additionally, the CNT based wires can be connected in near arbitrary configurations. This configurability enables opposing electrodes to be spaced less than 100nm apart. Such a dense electrode structure may lead to significant performance benefits for solid oxide fuel cells, organic photovoltaics, batteries and supercapacitors.

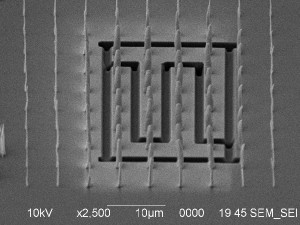

Figure 2: Scaled up interdigitated electrode test structure. 20nm of focused ion beam deposited tungsten on 80nm diameter carbon nanotubes.

The electrode structure is formed with a series of electron beam lithography liftoff processes to pattern the electrode traces and the CNT catalyst. Aligned CNTs are then grown via PECVD. The CNTs are metalized, either by focused ion beam assisted CVD or eBeam evaporation. The final step is to separate the two electrodes by focused ion beam milling.

A scaled up proof of concept has been fabricated to demonstrate the feasibility of this manufacturing process. Figure 1 shows the electrode structure just after CNT growth. The diameter of the nanotubes is approximately 80nm, the length is approximately 3µm, and spacing is 5µm. Figure 2 shows the test structure after metallization and ion milling. Resistivity measurements show resistance between joined CNTs on the order of 100Ω and between unconnected CNTs on the order of 100kΩ. Work to improve electrode isolation and scale the test structure is ongoing.

References

- A.I. Hochbaum and P. Yang, “Semiconductor Nanowires for Energy Conversion,” Chemical Reviews, vol. 110, no. 1, pp. 527-546, 2009. [↩]

- L. Cui, R. Ruffo, C. Chan et al., “Crystalline-Amorphous Core- Shell Silicon Nanowires for High Capacity and High Current Battery Electrodes,” Nano Letters, vol. 9, no. 1, pp. 491-495, 2008. [↩]