Low-profile Wearable Thermoelectric Generators

This report addresses the efficient utilization of energy from a thermoelectric module using a low-profile, wearable heat sink. Previous work on body-heat powered electronics has employed conventional heat sink designs originally developed for the electronics industry. Conventional heat sinks are optimized for large heat transfer from the small footprint typical of an integrated circuit. This optimization yields high-aspect ratio fin- and pin-heat sinks. These heat sinks cover a small fraction of the body’s surface area and protrude from the surface by as much as several centimeters. State-of-the-art commercial heat sinks for natural air convection include the pin-heat sink using a single, molded aluminum part (see left inset in Figure 1).

Here we demonstrate fabrication of a much more practical and comfortable heat-sink by taking advantage of the large available surface area for body-wearable thermoelectrics. We fabricated wrist-band style heat sinks using copper, with thicknesses from 1-1.5 mm.

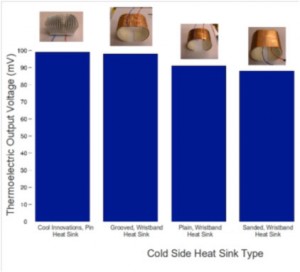

Figure 1: The three copper wristbands performed competitively and produced output voltages comparable with leading heat sinks in today’s market.

We tested the performance of these heat sinks by integrating them into a wearable thermoelectric energy-harvester consisting of a thermoelectric module, wristband heat sink, and a thermally insulating ceramic felt. The hot side of the module touches the arm, which acts as the heat source. This difference in temperature between the hot and cold sides produces the desired temperature differential and results in a voltage from a BiTe thermoelectric module.

Three variations of copper heat sinks were tested: the plain/flat, sanded, and grooved surfaces. The result of the experiments is shown in Figure 1. The steady-state voltage for the state-of-the-art pin-heat sink was 104 mV and the grooved wristband heat sink was 103 mV.

In conclusion, the low-profile, wearable thermoelectric heat sink provided competitive output voltages and also eliminated the uncomfortable nature of most standard heat sinks.