Integrated CMOS DC-DC Converter with Digital Maximum-power-point Tracking for a Portable Thermophotovoltaic Power Generator

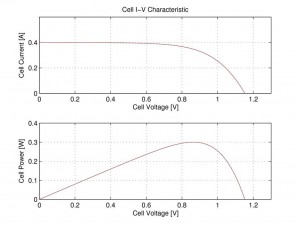

Figure 1: I-V (top) and P-V (bottom) characteristics of the TPV cell used in this work for a typical operating point. VMPP=0.8-1V, IMPP=350-400mA.

This work describes the design, optimization and evaluation of the power electronics circuitry for a low-power portable thermophotovatic (TPV) generator system. The TPV system is based on a silicon micro-reactor design and low-bandgap photovoltaic (PV) diodes [1].

TPV offers electric power generation with many benefits, such as no moving parts, high power density and mixed-fuel operation. However, the non-linear I-V characteristics of photovoltaic cells (Figure 1) necessitate power electronics to ensure that the cells are operating at their maximum power point. In this work, we implement a digital control algorithm to reach the maximum power point with a hill-climb method. To enable high-efficiency operation, we implement a new low-power digital pulse-width modulator circuit architecture that offers significant power saving compared to conventional approaches. In addition, a low-power counting-based ADC is employed for current and voltage sensing, which further reduces power losses. For power measurement, lossless current sensing technique is developed by employing the parasitic resistance of the inductor as the sensing element. This technique introduces no extra loss element and enables higher efficiency and a compact design. A tracking efficiency above 99% is achieved on an experimental prototype.

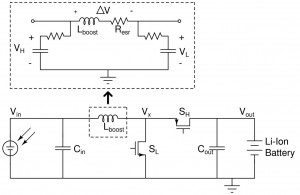

A boost converter (Figure 2) is used to converter the low-voltage output (VMPP=0.8-1V) from the TPV cell to higher voltages (3.6-4.2V) for Li-ion battery charging applications. The converter’s MOSFETs sizes are optimized for operation frequency of 1MHz and output power of 350mW by balancing the capacitive switching losses and the conduction loss. In addition, a soft-switching technique is used to further improve the converter’s performance. A self-adjusting dead time control circuitry is designed to achieve soft-switching in the converter. Efficiency of over 90% is achieved on Cadence simulation.

An integrated CMOS DC-DC converter with digital maximum-power-point tracker control is designed and fabricated in TSMC 0.35um 5V CMOS technology. The silicon chip has been received and is ready to be characterized.

References

- R. C. N. Pilawa-Podgurski, N. A. Pallo, W. R. Chan, D. J. Perreault, I. L. Celanovic, “Low-power maximum power point tracker with digital control for thermophotovoltaic generators,” Applied Power Electronics Conference and Exposition (APEC), 2010 Twenty-Fifth Annual IEEE, pp. 961-967, 21-25 Feb. 2010. [↩]