Growth of Vertically Aligned Carbon Nanotubes on a Continuously Moving Substrate

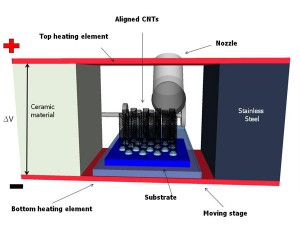

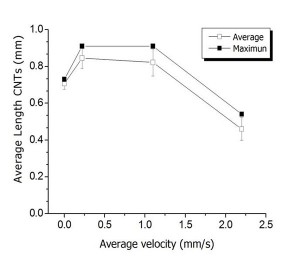

Vertically-aligned carbon nanotube (CNT) arrays are grown on a moving substrate, demonstrating continuous growth of nanoscale materials with long-range order. A cold-wall chamber with an oscillating moving platform (Figure 1) is used to locally heat a silicon growth substrate coated with a Fe/Al2O3 catalyst film for CNT growth via chemical vapor deposition. The reactant gases are introduced over the substrate through a directed nozzle to attain high-yield CNT growth. Aligned multi-wall carbon nanotube (MWNT) arrays (or “forests”) with heights of ≈1 mm are achieved at substrate speeds up to 2.4 mm/s. Arrays grown on moving substrates at different velocities are studied to identify potential physical limitations of repeatable and fast growth on a continuous basis. No significant differences are noted between static and moving growth as characterized by SEM and Raman spectroscopy, although overall growth height is marginally reduced at the highest substrate velocity. CNT arrays produced on moving substrates are also found to be comparable to those produced through well-characterized batch processes consistent with a base-growth mechanism. Growth parameters required for the moving furnace are found to differ only slightly from those used in a comparable batch process; thermal uniformity appears to be the critical parameter for achieving large-area uniform array growth. If the continuous-growth technology is combined with a reaction zone isolation scheme common in other types of processing (e.g., in the manufacture of carbon fibers), large-scale dense and aligned CNT arrays may be efficiently grown and harvested for numerous applications including interlayers for advanced composite reinforcement and improved electrical and thermal transport [1].

- Figure 1: Moving stage system where a Fe/Al2O3-deposited silicon wafer substrate is driven by an external motor through the growth zone that is comprised of two heaters (red) in a “toaster” configuration.

- Figure 2: Maximum and average heights of the center region (between 2.5 and 7.5 mm) of CNT array growth for different substrate velocities.

References

- R. Guzman de Villoria, S.L. Figueredo, A.J. Hart, S.A. Steiner III, A.H. Slocum, and B.L. Wardle, “High-yield growth of vertically aligned carbon nanotubes on a continuously moving substrate,” Nanotechnology, vol. 20, no. 40, 405611 (pp. 1-8), , 2009. [↩]