Energy-combining from Multiple Harvesters and a Shared Inductor

Stellar circuit designs have enabled us to have intelligent systems with extremely low power. These systems are low-duty cycled and often are used for monitoring patient health or industrial processes. Even with the advances in battery technology, these systems may still require battery replacement which will be the dominant cost. Energy harvesting offers an alternative in such cases. However, presence of the energy is sporadic making circuits powered by energy harvesters unreliable. Combining energy from different harvesters would increase the reliability of such systems.

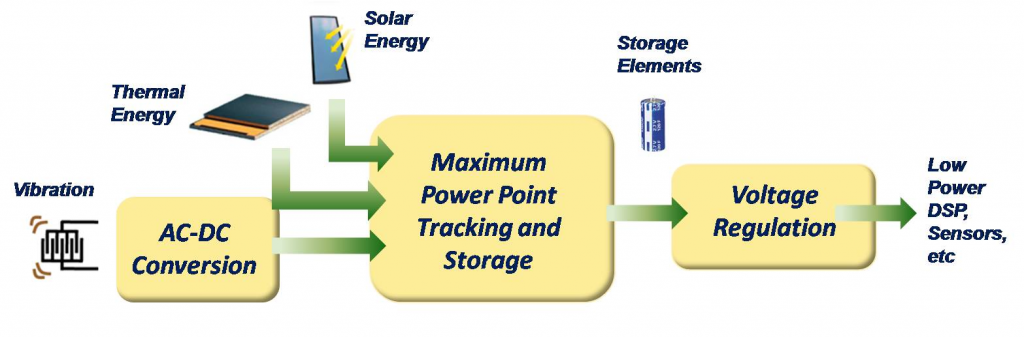

A system combining solar, vibration [1] and thermal energy [2] is being developed. The block diagram of the system is shown in Figure.1. In order to minimize the system form factor, inductor sharing has been done. It has been shown that the maximum power transfer from a thermal and vibration harvester is a one-time setting of the circuit. Solar harvesters instead need a constant maximum-power-point-tracking loop (MPPT) [3]. A novel MPPT scheme is being developed to enable an autonomous system with high tracking efficiencies.

References

- N.J. Guilar, et al. “An Energy-Aware Multiple Input Power Supply with Charge Recovery for Energy Harvesting Applications,” ISSCC Dig. Tech. Papers, pp. 298-299, Feb. 2009. [↩]

- Y.K. Ramadass and A.P. Chandrakasan, “A Batteryless Thermoelectric Energy-Harvesting Interface Circuit with 35mV Startup Voltage,” ISSCC Dig. Tech. Papers, pp. 486-487, Feb. 2010. [↩]

- T. Esram, P.L. Chapman, “Comparison of Photovoltaic Array Maximum Power Point Tracking Techniques,” IEEE Transactions on Energy Conversion, vol.22, no.2, pp. 439-449, June 2007. [↩]