A 1-mW, 25-Hz Vibration Energy Harvesting System

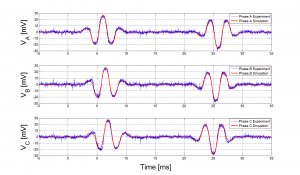

Figure 1: Loaded harvester waveforms from each of the three coils. Combined, they deliver 1.7mW of power to a resistive load. The simulated harvester voltages are shown for comparison.

This project is part of the Hybrid Insect-MEMS (HI-MEMS) program sponsored by the Defense Advanced Research Projects Agency (DARPA). The HI-MEMS program aims to steer a flying insect using an electronic interface to its nervous system. Thus, the objective is to gain wireless remote control over its motion during flight. In order to provide sustainable energy for the electronic control components mounted on the insect, a lightweight energy harvesting system must also be attached. The energy harvesting system presented here converts the 25-Hz wing beat vibrations produced by the insect during flight into electrical power via magnetic induction. Here, the insect is a moth.

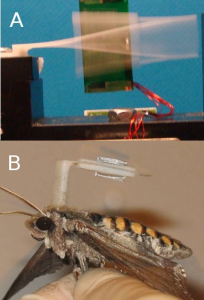

Figure 2: (A) A prototype mechanical harvester is mounted on a shaker table that simulates moth vibrations. The magnets sweep past the coils, which are printed on the thin, flexible green circuit board in the picture. (B) A harvester without the coils is shown, affixed to a moth.

This energy-harvesting system has two major parts: the mechanical harvester (Figure 2) and the boost converter. The mechanical harvester consists of a lightweight plastic resonator tuned to 25-Hz, neodymium iron boron magnets, and a flat coil printed on a flexible circuit board for good flux linkage and low mass. As the insect vibrates, the resonator amplifies the motion. Magnets attached to the resonator swing past the coil, generating electrical power. The total harvester mass is approximately 1 gram. Output waveforms generated by the magnet swing are shown in Figure 1.

The AC-DC boost converter rectifies the output of the harvester and boosts it to 1 volt. The converter consists of two stages of voltage gain, with off-chip inductors for increased efficiency. A discrete implementation of the electronics attached to the harvester has delivered 0.8 mW of time-average power at 1 V. In addition, a 0.18-μm integrated CMOS implementation has been fabricated and should yield greater efficiency due to reduced gate-drive parasitics.