Growth and Characterization of Carbon Nanotube Carpets for Electrochemical Applications

Improvements in electrochemical devices for energy storage, such as in Li-ion batteries and ultracapacitors, are being aggressively investigated due to demand for small and lightweight batteries with high energy densities and capacitors for high power. There are many benefits to fabricating nanostructured electrodes for these devices [1]. Carbon nanotube (CNT) arrays show immense promise as electrodes due to the high aspect ratios, electrical conductivity, and mechanical rigidity of CNTs.

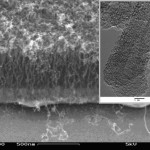

Carbon nanotubes are typically grown using transition metal catalysts, such as Fe. The catalyst morphology has a direct influence on the resulting nanotube diameter and areal density. We have demonstrated control of catalyst coarsening by changing the time of the introduction of H2 during CVD growth for nanotubes grown on insulating substrates [2]. This technique allows the modulation of tube properties and carpet morphology. Additionally, we have demonstrated low-temperature growth on conductive substrates, enabled by gas preheating [3] and rapid sample insertion into the growth zone in concert with an appropriate catalyst-substrate combination [4]. An example of crystalline tubes grown on conductive substrates is shown in Figure 1.

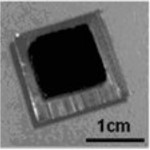

In order to explore the effect of nanotube carpet density on electrochemical device performance, we mechanically densify nanotube carpets using a technique developed by Wardle et al. [5]. This densification process is performed on CNTs grown on insulating substrates requiring the development of a process for transferring nanotubes to conductive substrates as illustrated in Figure 2. In addition to investigating densified nanotube carpets, we also plan to explore composite electrode structures for Li-ion batteries composed of CNT-supported nanoparticle Li intercalation materials.

- Figure 1: Carpet of vertically-aligned CNTs grown on a conductive substrate at 475°C. The catalyst/underlayer system is Fe/Ta. The HRTEM image on the inset shows the crystalline nature of the CNTs (scale bar 5 nm).

- Figure 2: Tall (2 mm) vertically-aligned carbon nanotube carpet transferred to Ni foil using a Ni-loaded conductive epoxy enabling densified nanotube carpets to be integrated into electrochemical devices.

References

- Y.G . Guo, J. S. Hu, G., and L. J. Wan, “Nanostructured Materials for Electrochemical Energy Conversion and Storage Devices,” Advanced Materials, vol. 20, pp. 2878-2887, August 2008. [↩]

- G.D. Nessim, A. J. Hart, J. S. Kim, D. Acquavia, J. Oh, C. D. Morgan, M. Seita, J. S. Leib, and C. V. Thompson, “Tuning of Vertically-Aligned Carbon Nanotube Diameter and Areal Density through Catalyst Pre-Treatment.” Nano Letters, vol. 8, pp. 3587-3593, November 2008. [↩]

- G. D. Nessim, M. Seita, K. P. O’Brien, A. J. Hart, R. K. Bonaparte, R. R. Mitchell, and C. V. Thompson, “Low Temperature Synthesis of Vertically Aligned Carbon Nanotubes with Electrical Contact to Metallic Substrates Enabled by Thermal Decomposition of the Carbon Feedstock,” Nano Letters, vol. 9, pp. 3398-3405, October 2009. [↩]

- G.D. Nessim, D. Acquaviva, M. Seita, Kevin P. O’Brien, and C.V. Thompson, “The Critical Role of the Underlayer Material and Thickness in Grown Vertically Aligned Carbon Nanotubes and Nanofibers on Metallic Substrates by Chemical Vapor Deposition,” Adv. Funct. Mat. 20 (2010). [↩]

- B. L. Wardle, D. S. Saito, E. J. Garcia, A. J. Hart, R. G. de Villoria, and V. P. Verploegen, “Fabrication and characterization of ultrahigh-volume-fraction aligned carbon nanotube-polymer composites,” Advanced Materials, vol. 20, pp. 2707-2714, July 2008. [↩]