Templated Self-assembly of Block Copolymers for Nanolithography

- Category: Nanotechnology

- Tags: caroline ross, karl berggren, kevin gotrik

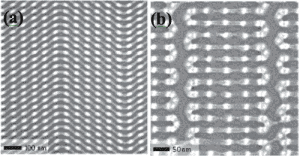

Self-organized macromolecular materials provide an alternative to conventional lithography for fabricating devices on the nanometer scale. Self-assembly of the microdomains of diblock copolymers within lithographically-defined templates to create patterns with long range order has attracted much attention; advantages include cost-effectiveness, large-area coverage, and compatibility with pre-established top-down patterning technologies. Block copolymers consist of two covalently bound polymer chains of chemically distinct polymer materials. The chains can self-assemble to form small-scale domains whose size and geometry depend on the molecular weights of the two types of polymer and their interaction. We showed that cylindrical morphology poly(styrene-b-dimethylsiloxane) (PS-PDMS) block copolymers, which have a large interaction parameter and high etch-contrast between two blocks, can be templated using an array of nanoscale topographical elements acting as surrogates for the minority domains of the block copolymer [1] and that combining the self-assembly of block-copolymer thin films with minimal top-down templating can generate complex nanoscale patterns. A sparse array of nanoscale HSQ posts accurately dictated the assembly of a cylindrical PS-PDMS diblock copolymer into complex, aperiodic features, as in Figure 1 [2] .

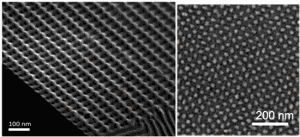

Recently, we have found strategies to control the self-assembly in three dimensions by functionalizing the HSQ posts with a majority-block brush. This brush allows us to guide multilayer films of PS-PDMS as shown in Figure 2a [3] , where the self-assembly of a crossbar structure is shown. This strategy can make cross-point structures with junctions and connections between the layers of cylinders. We have also developed a continuous flow solvent annealing system which allows extensive control over the morphologies of the block copolymers, so that spheres, cylinders, lamellae, etc. can be formed from one polymer simply by adjusting the solvent vapor pressures.

Beyond the rather limited morphologies of diblock copolymers, ABC triblock polymer thin films provide a diversity of new structures such as high-density nano-ring structures [3] , and square arrays of dots or holes can also be achieved from a self-assembled PI-PS-PFS triblock terpolymer, as shown in Figure 2b [4] . Topographical templating enables these structures to be ordered.

- Figure 1: SEM images of highly organized and asymmetric complex cylindrical BCP patterns with an array of HSQ posts (brighter dots) prepared by electron-beam patterning. (a) Zig-zag pattern and (b) sharply bent meander structure.

- Figure 2a: Isometric view of the self-assembly of a 3D crossbar architecture resulting from an array of majority-block functionalized HSQ posts. b: Square array of PFS dots from a thin film of PI-b-PS-b-PFS triblock terpolymer. PI and PS have been removed by O2 RIE.

- I. Bita, J. K. W. Yang, Y. S. Jung, C. A. Ross, E. L. Thomas, and K. K. Berggren, Science, vol. 321, pp. 939-943, 2008. [↩]

- J. K. W. Yang, Y. S. Jung, J.-B. Chang, C. A. Ross, and K. K. Berggren, Nature Nanotechnology, vol. 5, pp. 256-260, 2010. [↩]

- A. T. K. Ghariehali, K. W. Gotrik, A. F. Hannon, A. Alexander-Katz, C. A. Ross, K. K. Berggren, Science, vol. 336, pp. 1294-1298, 2010. [↩] [↩]

- J. G. Son, J. Gwyther, J.-B. Chang, K. K. Berggren, I. Manners, and C. A. Ross, Nano Letters, vol. 11, pp. 2849-55, 2011. [↩]