Removable Template for Block Copolymer Directed Self-Assembly

- Category: Electronic Devices, Materials, Nanotechnology

- Tags: karl berggren, sam nicaise

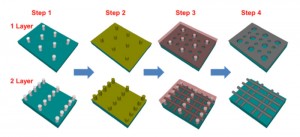

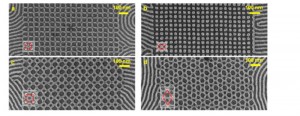

Self-assembled block copolymer structures are useful in nanolithography applications, producing patterns with high resolution and throughput. We previously showed control over the direction of in-plane cylindrical microdomains formed by self-assembly of a block copolymer (BCP) using a variety of physical templates made from hydrogen silsesquioxane (HSQ) resist [1] [2] . The HSQ templates were fabricated by electron-beam lithography and then functionalized with a minority or majority block brush to interact with the BCP and direct the self-assembly (as shown in Figure 1). However, HSQ templates were not easily removed and remained as part of the final pattern. Remaining HSQ caused non-uniform pattern transfer due to dissimilar etch rates between the BCP and HSQ. In this study, we solved this issue by using a removable-resist template coated with an etchable-block brush. We fabricated two- and three-dimensional BCP patterns and then removed the templates. Examples (Figure 2) include three-dimensional bends, junctions and mesh-shaped structures, and the ability to change the BCP morphology through templating.

The negative-tone-post templates were made by electron-beam lithography of poly (methyl methacrylate) (PMMA) resist at high dose (100-600 pC/pixel). After development of patterns using methyl isobutyl ketone (MIBK) and acetone ultrasonication, the surface of the patterns was coated with hydroxyl-terminated polystyrene (PS) brush (1 kg mol-1). Then poly(styrene-b-dimethylsiloxane) (PS-b-PDMS) BCP (MW=45.5 kg mol-1, f_PDMS=0.32, period 35 nm) was spun and solvent annealed with a mixture of heptane and toluene. CF4 and O2 reactive ion etch (RIE) was used to remove the top PDMS layer and the PS matrix. The O2 RIE not only removed not only the PS matrix but also removed the PMMA template in the same step. The final results were in-plane oxidized-PDMS cylindrical microdomain patterns in the form of two- and three-dimensional structures devoid of templates. This study provides a path to complex pattern formation for nanolithography with feature sizes below 20 nm.

- Figure 1: Schematic of the major steps of the method for the directed self-assembly using a removable template with an etchable-block brush. (Step 1) fabrication of the templates using EBL, a PMMA resist, (Step 2) functionalizing the templates with a PS brush, (Step 3) spin coating and annealing of the BCP, and (Step 4) removing the PS matrix and the PMMA template using oxygen RIE.

- Figure 2: Example SEMSs of single-layer ox-PDMS nanostructures fabricated by the sacrificial method. Shown are (a) square array of nanoholes, (b) square array of nanoposts, (c) square array of nanoholes with a hole generated by each PMMA post and (d) hexagona array of nanoholes with two holes generated by each PMMA post. Insets show the pre-removal locations of negative-tone PMMA posts in white. Red outlines represent unit cells for the final nanostructures. Light grey and dark grey colors represent ox-PDMS and the substrate, respectively.