Quantitative Analysis and Modeling of Templated Solid-state Dewetting of Thin Single-crystal Ni Films

- Category: Materials, Optics & Photonics

- Tags: alan gye hyun kim, carl thompson

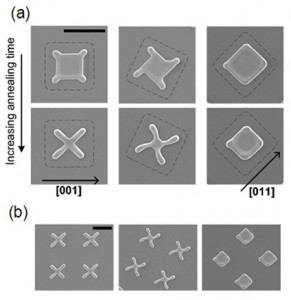

Because thin films are usually unstable in the as-deposited state, at sufficiently high temperatures atomic motion will occur and lead films to dewet or agglomerate to form arrays of islands. This can occur well below the melting temperature when the films are still solid. In single-crystal films, due to anisotropy in surface energy and diffusivity, this dewetting process occurs to form regular arrays of islands. When this process is templated through pre-patterning of the film, this process becomes a potential self-assembly method to generate complex and reproducible patterns much smaller than the original templates (a simple example is shown in Figure 1). Quantitative understanding of such dewetting phenomena is critical in controlling the dewetting morphology for self-assembly. We have measured the rates of anisotropic edge retraction due to solid-state dewetting in kinetically stable crystallographic orientations. An understanding of the retraction of these orientations allows modeling for edges with other orientations that are composed of microfacets [1] . We have also developed a model for the effects of anisotropy on edge retraction using crystalline formulation. This model is used as a prediction tool to reproduce the experimental result. Agreement between the model and experiments is generally good and provides a starting point for development of models that explain the evolution of edges with corners. These models will provide a predictive tool for relating pre-patterned structures to desired more complex dewetted structures.

- Figure 1: SEM images of dewetting of 120-nm-thick square patches of single-crystal Ni with three different in-plane orientations patterned from a (110) film. Grey dashed lines indicate the original square patterned shapes [2] . Scale bars indicate 10 µm.

- Figure 2: Retraction rates of edges in kinetically stable degrees of single-crystal Ni(100) and Ni(110) films. The samples were annealed at 900 °C under 2310 sccm reducing gas (5% H2 95% N2). The experimental data are compared with a model that takes into account the effects of surface energy anisotropy. No fitting parameters were used. Appropriate equilibrium Winterbottom shapes are obtained using The Wulffenator [3] , a program for equilibrium shape generation.

- W. C. Carter, A. R. Roosen, J. W. Cahn and J.F. Taylor, “Shape evolution by surface diffusion and surface attachment limited kinetics on completely faceted surfaces,” Acta Metallurgica Materialia, vol. 95, p. 12, 1995. [↩]

- J. Ye and C. V. Thompson, “Templated solid-state dewetting to controllably produce complex patterns,” Advanced Materials, vol. 23, p. 1567, 2011. [↩]

- R. V. Zucker and W. C. Carter, unpublished research. [↩]