Nano-electromechanical System Digital Switches

- Category: Materials, MEMS & BioMEMS

- Tags: annie wang, farnaz niroui, jeffrey lang, vladimir bulovic

Nano-electromechanical systems (NEMS) are an emerging area of research with potential applications as low-power switches for electronic circuits. The proliferation of electronics in both stationary and portable applications demands the development of more energy-efficient devices than are currently available. While solid-state silicon MOS-based transistor circuits, the dominant technology in today’s electronics, have greatly reduced their power requirements by aggressive scaling, the concurrent increase in off-state leakage current limits their energy efficiency. In contrast, microelectromechanical relays have been demonstrated with zero off-state currents and abrupt switching characteristics [1] [2] . As these and other electromechanical devices are shrunk to the nanoscale, their actuation voltages, and hence power requirements, are expected to be reduced significantly.

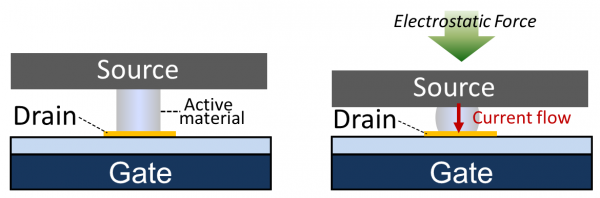

Our group recently presented a three-terminal electromechanical switch based on a piezoresistive polymer nanocomposite as the active material [3] . The metal-polymer composite consisted of a polydimethylsiloxane polymer matrix doped with 60 wt% nickel particles. A schematic diagram of this squeezable switch, or “squitch,” is shown in Figure 1. In its initial state, the conductive metal particles are separated by the insulating polymer matrix. Thus, the active material is highly resistive, and little current flows through the device (in the “off” state). When compressed, the metal-metal distances decrease until the onset of tunneling allows current to flow from source to drain (“on” state). The first-generation squitch demonstrated transistor-like behavior with drain-source conduction modulation over 4 orders of magnitude when electromechanical force was applied. However, the large mechanical dimensions of this concept demonstration necessitated higher supply voltages than desired. Our current work focuses on incorporating the squitch concept into nanoscale devices by (a) developing improved device structures and fabrication methods and (b) exploring new materials such as ligand-coated nanoparticles and self-assembled monolayers as active materials.

Figure 1: Schematic diagram of squitch. Applying a voltage bias between gate and source generates an electrostatic force that compresses the active material and allows carriers to tunnel from source to drain. When the voltage bias is removed, the active material acts as a mechanical spring and recovers from its compressed state to cut off current flow through the device.

- M. Spencer, F. Chen, C. C. Wang, R. Nathanael, H. Fariborzi, A. Gupta, K. Hei, V. Pott, J. Jaeseok, L. T.-J. King, D. Markovic, E. Alon, and V. Stojanovic, “Demonstration of integrated micro-electro-mechanical relay circuits for VLSI applications,” IEEE Journal of Solid-State Circuits, vol. 46, pp. 308-320, January 2011. [↩]

- R. Parsa, M. Shavezipur, W. S. Lee, S. Chong, D. Lee, H. S. P. Wong, R. Maboudian, and R. T. Howe, “Nanoelectromechanical relays with decoupled electrode and suspension,” in IEEE 24th International Conference on Micro Electro Mechanical Systems, 2011, pp. 1361-1364. [↩]

- S. Paydavosi, F. M. Yaul, A. I. Wang, F. Niroui, T. L. Andrew, V. Bulovic, and J. H. Lang, “MEMS switches employing active metal-polymer nanocomposites,” in IEEE 25th International Conference on Micro Electro Mechanical Systems, 2012, pp. 180-183. [↩]