InAsP Graded Buffers for Thermophotovoltaic Devices

- Category: Energy, Materials

- Tags: adam jandl, eugene fitzgerald

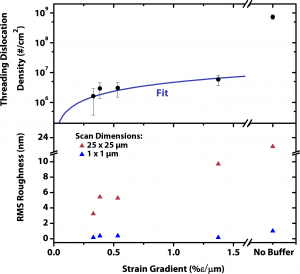

Figure 1: The threading dislocation density (TOP) in InAsxP1-x graded buffers does not significantly increase with higher strain gradients. The threading dislocations appear to be highly mobile with a calculated velocity of 40.9 μm/s at the growth temperature. This velocity was found by fitting the data with a least-squares regression (the “No Buffer” sample was not included). Increased strain gradients do cause a marginal increase in the RMS surface roughness (BOTTOM). RMS roughness was calculated from a 25×25 μm AFM image.

Semiconducting alloys of InxGa1-xAs, GaAsySb1-y, and InAszP1-z can be fabricated to exhibit band gaps between 0.5 and 1.0 eV, which are suitable for thermophotovoltaic (TPV) devices. However, the compositions of interest are not lattice-matched to any of the common III-V compound semiconductor substrates. Direct growth of these alloys on common substrates would result in high threading dislocation densities (TDD) in the active layers. Since TPV devices require long minority carrier lifetimes, the dislocation density needs to be minimized for efficient performance. The objective of our research is to establish robust lattice constant engineering approaches to allow broad tunability of the band gap of TPV devices. We have researched the properties of compositionally graded buffers of InAszP1-z on InP substrates to provide a platform for high quality thin films of InxGa1-xAs, GaAsySb1-y, and InAszP1-z alloys over a range of lattice constants and band gaps.

InAsxP1-x compositionally graded buffers were prepared with metal-organic chemical vapor deposition (MOCVD) system. A set of samples was fabricated to study the TDD evolution as a function of the strain gradient (% strain/µm) in the buffer. The samples consisted of graded buffers with strain gradients between 0.33 % strain/μm and 1.37 % strain/μm and final cap composition of InAs0.4P0.6. One sample included in this set was a layer of InAso.4Po.6 grown directly on InP that intentionally lacked a graded buffer. Figure 1 shows the threading dislocation density and surface roughness for this set of samples. Assuming an equilibrium strain relaxation process, we determined the dislocation glide velocity in the InAsxP1-x graded buffers to be 40.9 μm/s using a least-square fit of the data. This velocity is relatively high and allows for low dislocation densities for high strain gradients. Although surface roughness increases with strain gradient, the greatest roughness was still suitable for device processing.