Batch-Microfabricated Electrospray Arrays with Integrated Electrode Stack for Ionic Liquids

- Category: MEMS & BioMEMS

- Tags: frances hill, luis velasquez-garcia, philip ponce de leon

Electrospray is a process to ionize electrically conductive liquids that relies on strong electric fields; charged particles are emitted from sharp tips that serve as field enhancers to increase the electrostatic pressure on the surface of the liquid, overcome the effects of surface tension, and facilitate the localization of emission sites. Ions can be emitted from the liquid surface if the liquid is highly conductive and the emitter flowrate is low. Previous research demonstrated successful operation of massive arrays of monolithic batch-microfabricated planar electrospray arrays with an integrated extractor electrode using ionic liquids EMI-BF4and EMI-Im [1] [2] – liquids of great importance for efficient nanosatellite propulsion. The current work aims to build upon the previous electrospray array designs by increasing the density of the emitter tips, increasing the output current by custom-engineering suitable nanofluidic structures for flow control, and improving the ion optics to gain control of the plume divergence and exit velocity.

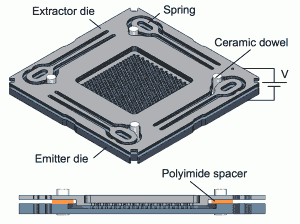

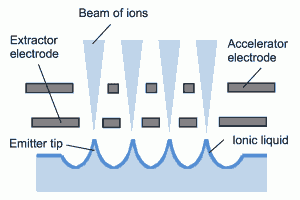

The basic version of the MEMS electrospray array consists of an emitter die and an extractor die (shown in Figure 1), both made of silicon and fabricated using deep reactive ion etching. The two dies are held together using a MEMS high-voltage packaging technology based on microfabricated springs that allows precision packaging of the two components with less than 1% beam interception [3] [4] . The emitter die contains dense arrays of sharp emitter tips with as many as 1,900 emitters in 1 cm2. A voltage applied between the emitter die and the extractor electrode creates the electric field necessary to ionize the ionic liquid (see Figure 2). A nanostructured material transports the liquid from the base of the emitters to the emitter tips. The present research focuses on engineering the nanofluidic structure to attain higher emitter current while maintaining good array emission uniformity and on developing batch microfabricated advanced ion optics to control the electrospray plume.

- Figure 1: Design of the basic version of the MEMS electrospray array, consisting of an emitter die and an extractor die.

- Figure 2: Schematic of externally fed electrospray emitter tips and the electrodes that create an electric field to produce a beam of ions.

- L. F. Velásquez-García, A. I. Akinwande, and M. Martínez-Sánchez, “A planar array of micro-fabricated electrospray emitters for thruster applications,” Journal of Microelectromechanical Systems, vol. 15, no. 5, pp. 1272-1280, Oct. 2006. [↩]

- B. Gassend, L. F. Velásquez-García, A. I. Akinwande, and M. Martínez-Sánchez, “A microfabricated planar electrospray array ionic liquid ion source with integrated extractor,” Journal of Microelectromechanical Systems, vol. 18, no. 3, pp. 679-694, June 2009. [↩]

- B. Gassend, L. F. Velásquez-García, and A. I. Akinwande, “Precision in-plane hand assembly of bulk-microfabricated components for high voltage MEMS arrays applications,” Journal of Microelectromechanical Systems, vol. 18, no. 2, pp. 332-326, 2009. [↩]

- L. F. Velásquez-García, A. I. Akinwande, and M. Martínez-Sánchez, “Precision hand assembly of MEMS subsystems using DRIE-patterned deflection spring structures: An example of an out-of-plane substrate assembly,” Journal of Microelectromechanical Systems, vol. 16, no. 3, pp. 598–612, 2007. [↩]