Single-Chamber Deposition of Multilayer Barriers

- Category: Energy, Materials

- Tags: Anna Coclite, Karen Gleason

Protective coatings that prevent the ingress of water into electronic devices fabricated on flexible plastic substrates are essential to extend the device’s lifetime. Widely investigated barrier protective coatings are multilayer stacks where dense, inorganic layers are alternated with soft, organic ones [1] . The possibility of a single-chamber system may greatly simplify the production and allows the quicker and cheaper roll-to-roll deposition.

A new technique consisting of coupling initiated CVD (iCVD) and PECVD was investigated for the multilayer deposition, maintaining the same precursor and the same reactor configuration [2] . Multilayer coatings of alternating silica-like and organosilicon layers were deposited using hexavinyldisiloxane (HVDSO) as a precursor.

Chemical and morphological characterization of the organic layer showed that the iCVD of HVDSO resulted in a very crosslinked film with high carbon content (79% from XPS analysis), low roughness (0.7 nm), and planarizing properties. PECVD of the same monomer, highly diluted in oxygen, gave an inorganic coating with a low content of OH terminal groups. When the inorganic layer was deposited over the organic layer, a graded interphase (40 nm) was detected, due to plasma ion bombardment.

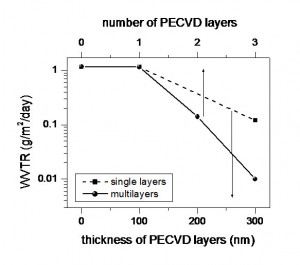

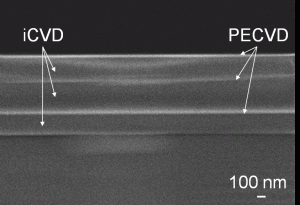

Figure 1 shows the results on the moisture barrier permeation tests for the single inorganic PECVD layers and for the multistack structures. A barrier improvement factor of 100 over the single inorganic layer was obtained with a hexalayer. The ‘‘orders-of-magnitude’’ improvement in the barrier performance made by adding organic/inorganic dyads is a signature of an effective defect decoupling. The organic layers, despite lacking the intrinsic barrier properties, produce a synergistic improvement in the performance when coupled with inorganic layers. Interesting is the comparison between the WVTR of the 300-nm-thick single PECVD layer and of the hexalayer containing three 100-nm-thick PECVD layers (whose cross-sectional micrograph is shown in Figure 2). These two structures have the same total inorganic layer thickness, but the multilayer has ten times better performance.

- Figure 1: Water vapor transmission rate (25°C, 98% RH) of barrier films as function of the film thickness and of the number of the C-depleted layers in the multistacks.

- Figure 2: FEG-SEM micrograph of a hexalayer composed of three SiOx –like / SiOxCyHz dyads. The dark layers are iCVD SiOxCyHz, and the bright ones are PECVD SiOx-like.

- P. E. Burrows, G. L. Graff, M. E. Gross, P. M. Martin, M. K. Shi, M. Hall, E. Mast, C. Bonham, W. Bennett, and M. B. Sullivan, Ultra barrier flexible substrates for flat panel displays, Displays, vol. 22, p. 65, 2001. [↩]

- A. M. Coclite, G. Ozaydin-Ince, F. Palumbo, A. Milella, and K. K. Gleason, Single-Chamber Deposition of Multilayer Barriers by Plasma Enhanced and Initiated Chemical Vapor Deposition of Organosilicones, Plasma Proc. Polym., vol. 7, p. 561, 2010. [↩]