MEMS Space Thrusters: The ion Electrospray Propulsion System (iEPS)

- Category: MEMS & BioMEMS

- Tags: Paulo Lozano

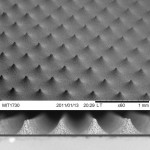

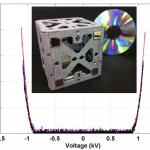

Electric Propulsion (EP) brings benefits for space missions requiring relatively large changes in satellite velocity, for example by reducing the propellant mass compared to traditional, less fuel-efficient chemical engines. Introducing EP in small satellites would enable them to perform interesting missions, such as long term attitude control/drag cancellation, orbital modification and, perhaps, deep space travel [1] . However, most EP technologies are challenging to miniaturize to the required levels, especially for nano/pico-satellites. Our group has developed an ion Electrospray Propulsion System (iEPS) as a candidate of an EP technology amenable for efficient miniaturization. The thruster core is based on a porous metal structure, which is bonded to an oxidized silicon package frame, followed by masking of the metal with a pattern of circles. The metal is then electrochemically etched in a regime that prevents material removal inside the pores, thus forming an array of porous tips [2] , as shown in Figure 1. To finalize the device, an extractor silicon grid with a matching array of holes and coated with a gold film is aligned and bonded to the frame holding the porous metal. Electrical isolation is provided by the bonding material and grown silicon oxide layers. A zero vapor pressure ionic liquid (the propellant) is then injected to the device from the back through a port in the silicon frame. The liquid wicks through the porous structure reaching the tips. Ion emission is the produced when applying a voltage of about 1kV between the metal and extractor grid. Figure 2 shows a typical I-V curve and a picture finished devices on a CubeSat [3] . A thruster pair should be able to produce 60-70 micro-N, enough to raise the orbit of a 1 kg CubeSat by 400 km in about 25 days of operation consuming 6-7 grams of propellant with 1W of power.

- Figure 1: SEM image of electrochemically etched porous metal tips. Each emitter is about 150 micron tall. The array pitch is 450 micron.

- Figure 2: Typical abs(I)-V curve for an iEPS device. The corresponding thrust is about 0.1 microN/microA. Also shown here is a photograph of 4 finished thrusters at the corners of a 10 cm CubeSat, including the power processing unit.

- P.C. Lozano and D. Courtney, “On the development of high specific impulse electric propulsion thrusters for small satellites”, 1915685, The Small Satellites Systems and Services – The 4S Symposium, Funchal, Madeira, Portugal, May 30 – June 4, 2010. [↩]

- R. Legge and P. Lozano, “Electrospray propulsion based on emitters microfabricated in porous metals,” Journal of Propulsion and Power, vol. 27, no. 2, 2011, pp. 485-495. [↩]

- D. Courtney, Ph.D. Thesis, Department of Aeronautics and Astronautics, MIT 2011 [↩]